5238-E P-209

SECTION 8 LATHE AUTO-PROGRAMMING FUNCTION (LAP)

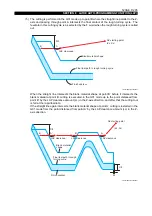

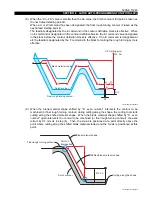

(10) Steps (10) and (11) are repeated until the most recessed section along the X-axis is cut. After it

has been cut, both the X- and Z-axis retract by 0.1 mm (radius value for the X-axis), and the X-

axis is positioned at the point whose coordinate value is "the first cutting level along the

descending slope D + 0.2" mm.

After the completion of descending slope cutting, the cutting previously in progress resumed

and steps after (4) are repeated.

The next infeed starting point is the point distanced from the point of intersection between the

line whose X-coordinate is "the first cutting level along the descending slope D - D" and the

blank material shape, by the LAP clearance amount (Lc).

LE33013R0301000230008

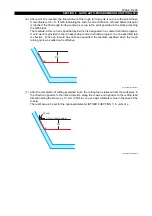

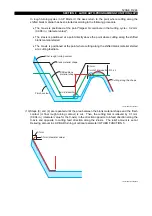

(11) The steps described above are repeated until the X-axis reaches the level where a tool path is

generated below "Xa + U". When such a level is reached, the final rough cutting is carried out

along the contour, leaving the finish cut allowance.

The feedrate in cutting along the final rough cut contour is the one specified by the E word.

After the completion of the final rough turning step, the X- and Z-axes are relieved by 0.1 mm

(0.004 in.) (diameter value for the X-axis). The relief amount is set at Relieving amount in LAP-

BAR turning of optional parameter (OTHER FUNCTION 1).

LE33013R0301000230009

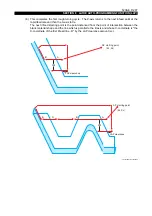

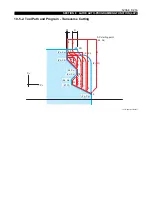

Feedrate Ef

Eg

Ee

1st path with depth of cut "D" in

current descending slope cutting

(Zc, Xc)

(Zc, Xb)

(Za, Xa)

W

0.1mm

0.1mm (radius value)

Ec

Eb

B

U/2