5238-E P-84

SECTION 6 OFFSET FUNCTION

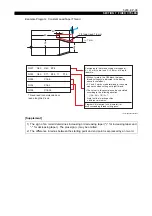

If block N5 containing G40 has no I and K words, positioning of the cutting tool by the commands in

block N4 is executed so that the tool nose R comes into contact with line N3 - N4 at designated point

N4 and then moves along the path indicated by broken lines toward point N5.

Addition of I and K words in block N5 positions the cutting tool to the point where the tool nose R is

brought into contact with straight line N3 - N4 and imaginary straight line N4 - N5’ when the

commands in block N4 are executed. Execution of the commands in block N5 brings the cutting tool

to the programmed point N5 where tool nose radius compensation is not active.

[Supplement]

Independent G40

When the G40 code is programmed without other commands in the same block, positioning is

carried out at the point where the tool nose R comes into contact with the point specified in the

previous block since the G40 block has no X and Z words which call for axis movement.

LE33013R0300800110007

When the tool nose radius compensation mode is canceled (G40), the mode of operation must be

either G00 or G01. If not, an alarm occurs.

1-8-5. Relieving Tool to Change "S" or "M" Code during Cutting

The tool nose radius compensation function is designed to automatically compensate the tool nose

radius in a continuous cutting program; with the dimensions of the workpiece programmed,

compensation is automatically applied to finish the part to the programmed dimensions. However,

such a powerful function requires careful programming when continuous cutting is interrupted to

change S and/or M commands.

This section deals with some programming examples in which the programmer experienced

unexpected results by relieving the cutting tool during cutting on a continuous path.

•

I and K words should be commanded as incremental values. In this case the dimensions are

referenced to point N4.

•

When either I or K only is specified without the other, the control interprets the word to have the

value "0". Therefore, K0 in the above program can be omitted.

N2

N3

N4

Z60

F0.2

X130 Z20

N1

G42

G01

N5

G40

N6

X300 Z300

G00

X100

X120

Z100

S1000

T010101

M03

X

+

Z

+

N4, N5

N6

N3

N2

N1