5238-E P-90

SECTION 6 OFFSET FUNCTION

2.

Cutter Radius Compensation Function

2-1.

Overview

This function automatically offsets the tool paths to generate the required shape in multi-processing

just by programming the final shape.

Using this function, cutters of different diameters can be used to machine workpieces of the same

shape without modifying the program.

2-2.

Programming

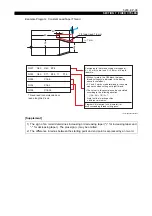

Designation of offset plane (G17, G18, G119)

[Function]

Changeover among the X-Z plane (nose R compensation), the X-Y plane (cutter radius

compensation on contour generation machining plane (face)), and C-X-Z plane (cutter radius

compensation on contour generation machining plane (side)) is possible by designating the

appropriate G code.

[Programming format]

[Details]

•

G17 and G119 are effective only while the C-axis is joined.

•

When the C-axis control cancel command (M109) is executed, the X-Z plane (G18) is

automatically selected.

•

When the power is turned on or the control is reset, the X-Z plane (G18) is selected.

Cutter radius compensation function ON/OFF (G40, G41, G42)

[Function]

Turn the cutter radius compensation function on and off by means of G codes.

[Programming format]

[Details]

•

In the G17 plane, compensation can be activated in the following G code modes.

G00, G01, G101, G102, G103

•

In the G119 plane, compensation can be activated in the following G code modes.

G00, G01, G132, G133

G17

: X-Y plane

(cutter radius compensation on contour generation machining plane, face)

G18

: X-Z plane (nose R compensation)

G119 : C-X-Z plane

(cutter radius compensation on contour generation machining plane, side)

G40 : Cutter radius compensation function OFF

G41 : Cutter radius compensation function, left

(viewed in the direction of tool advance, the tool is positioned at the left side of the

workpiece)

G42 : Cutter radius compensation function, right

(viewed in the direction of tool advance, the tool is positioned at the right side of the

workpiece)