5238-E P-202

SECTION 8 LATHE AUTO-PROGRAMMING FUNCTION (LAP)

The entries in programs A and B are described in 1) through 7) below.

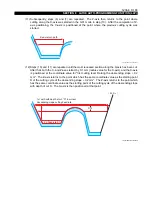

(1) Blank material shape definition start G code (G83)

•

This code declares the start of blank workpiece shape definition.

•

The blocks following the G83 block and followed by the G81 or G82 block define the blank

workpiece.

(2) Blank material shape definition block

•

Define the blank workpiece shape using the G01, G02, and G03 codes.

•

Note that the G00 code cannot be used.

•

An alarm occurs if the G02 or G03 code is specified in the first block that follows the G83

block.

(3) Finish contour definition start G code

•

This code declares the start of the finish contour definition.

•

The blocks following the G81 or G82 block and followed by the G80 block define the finish

contour.

•

G81 code: Longitudinal contour

G82 code: Transverse contour

(4) Finish contour definition blocks

•

Define the finish contour using the G00, G01, G02, and G03 codes.

•

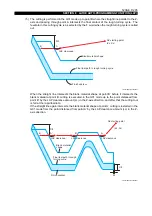

The tool retraction path after the completion of machining varies depending on whether the

first block contains the G00 or G01 code.

•

The G00 code can be used only in the first block.

•

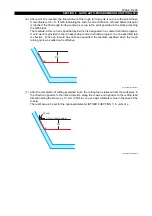

F: Feedrate in finishing

S: Spindle speed in finishing

•

E: Feedrate along contour in the high-speed bar turning cycle

•

F, E, and S commands are all modal.

(5) Contour definition end G code

This code declares the end of contour definition.

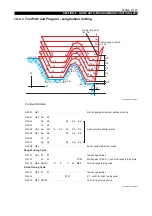

(6) Calls for rough turning cycle

•

The rough turning cycle is started by calling the contour definition blocks starting with G85.

•

When the contour definition blocks start with G83, the AP Mode IV (high-speed bar turning

cycle) is selected. (LAP4 only)

•

When the finish contour definition blocks start with G81 or G82, the AP Mode I (bar turning

cycle) is selected.