5238-E P-114

SECTION 7 FIXED CYCLES

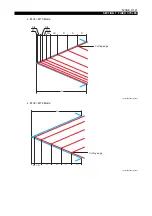

•

When M33 is designated

D

2

≥

{H

2

- (H - U (W))

2

}

The thread cutting cycle is repeated with the cutting point at each even numbered thread cutting

path being "D" until the cutting point of "H - U (W)" is reached. In each odd numbered tool

paths, the cutting point is calculated as;

LE33013R0300900150001

Finally, the cutting tool is fed by "U (W)" to carry out the finishing cycle. The finishing cycle is

not carried out if U (W) is not designated in the program.

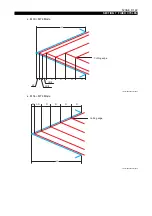

D

2

< {H

2

- (H - U (W))

2

}

In each thread cutting path, assume the thread cutting point d

1

(D) and metal removal volume

S

1

for the first path, d

2

and S

2

for the second path, and d

n

and S

n

for the "n"th path, then cutting

points d

2

to d

n

(n = even number) for the even numbered paths are determined so that S

2

to S

n

(n = even number) will be the most appropriate metal removal volume to provide high cutting

accuracy while minimizing the number of paths. For the odd numbered paths, the cutting point

is determined by

d

n

= 1/2 (d

n-1

+ d

n+1

) (d = odd number).

This cycle is repeated until the cutting point of "H - U (W)" is reached. Finally, the cutting tool is

fed by "U (W)" to carry out the finishing cycle. The finishing cycle is not carried out if U (W) is

not designated in the program.

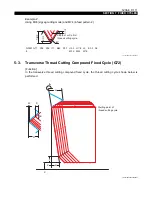

Infeed pattern 4

•

When M32, M34 is designated

The following pattern is created regardless of the values of H, D, and U(W).

In each thread cutting path, assume the thread cutting point d

1

(D) and metal removal volume

S

1

for the first path, d

2

and S

2

for the second path, and dn and Sn for the "n"th path, then cutting

points d

2

to d

n

are determined so that S

2

to S

n

will be the most appropriate metal removal

volume to provide high cutting accuracy while minimizing the number of paths. This cycle is

repeated until the cutting point of "H - U (W)" is reached. Finally, the cutting tool is fed by "U

(W)" to carry out the finishing cycle. The finishing cycle is not carried out if U (W) is not

designated in the program.

•

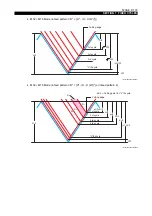

When M33 is designated

In each thread cutting path, assume the thread cutting point d

1

(D) and metal removal volume

S

1

for the first path, d

2

and S

2

for the second path, and dn and d

n

for the "n"th path, then cutting

points d

2

to d

n

(n = even number) for the even numbered paths are determined so that S

2

to S

n

(n = even number) will be the most appropriate metal removal volume to provide high cutting

accuracy while minimizing the number of paths. For the odd numbered paths, the cutting point

is determined by

d

n

= 1/2 (d

n-1

+ d

n+1

) (d = odd number).

This cycle is repeated until the cutting point of "H - U (W)" is reached. Finally, the cutting tool is

fed by "U (W)" to carry out finishing cycle. The finishing cycle is not carried out if U (W) is not

designated in the program.

[Supplement]

Since X commands are specified as diameter values, the actual infeed amount is "D/2".

When no infeed-pattern-designating M code is programmed, the control automatically selects

M73.

By combining the M codes designating cutting mode and infeed pattern, ten types of thread cutting

cycle each are available for longitudinal thread cutting and transverse thread cutting.

( n + 1

D +

n - 1

D )

1

2