5238-E P-210

SECTION 8 LATHE AUTO-PROGRAMMING FUNCTION (LAP)

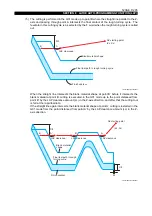

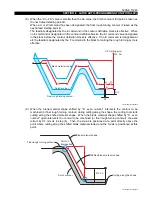

(12) At the completion of step (13), the axes return to the AP starting point (Xs, Zs).

There are two patterns of axis return motion:

The two axes return to the AP starting point simultaneously when G00 is designated in the first

block of the contour definition program (the block following the one containing either G81 or

G82).

When G01 is designated in the block indicated above, positioning is done on the X-axis first and

then the Z-axis returns to the AP starting point.

LE33013R0301000230010

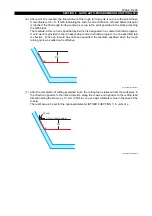

The tool does not return to the AP starting point as explained in step (14) when M85 is

designated in the block calling for the rough turning cycle (the block starting with G85).

This completes a rough turning cycle.

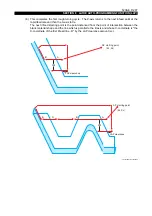

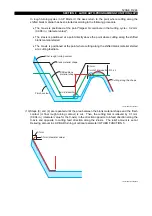

Finish turning cycle in high-speed bar turning in longitudinal direction (example A)

(1) The commands in block N0261 positioning the axes at the tool change position.

(2) With the commands in block N0262, S, T, and M commands for the finish turning cycle are

selected.

(3) In block N0263, the control searches the program assigned the program name N0608. The

finish turning cycle in the bar turning mode is performed using this program.

(4) The finish turning cycle is performed following the dimension data designated in the contour

definition program in the specified cutting conditions for the finish turning cycle.

(5) After the finish turning cycle is completed, the commands in the block following N0263 are

executed.

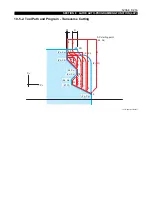

When the block following the G81 (G82)

block starts with G01:

When the block following the G81 (G82)

block starts with G00

AP starting point

(Xc, Xs)