5238-E P-129

SECTION 7 FIXED CYCLES

6-4.

Example Program for Transverse Grooving/Drilling Fixed Cycle

(G74)

Example: Drill cycle program

LE33013R0300900220001

[Supplement]

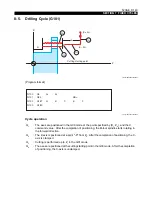

6-5.

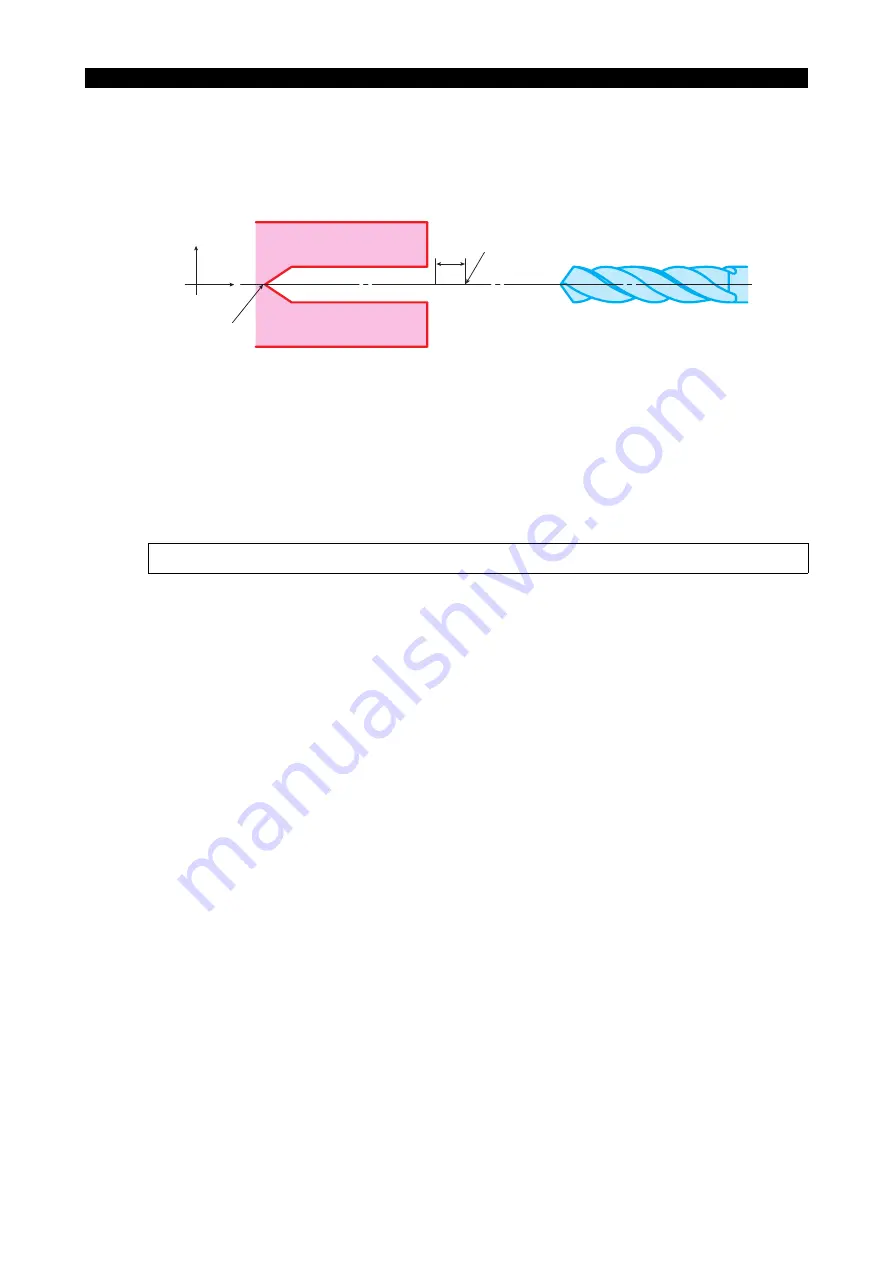

Axis Movements in Grooving/Drilling Compound Fixed Cycle

(1) The axis moves the amount specified by "I (K)" at a rapid traverse rate along the X (or Z) axis

from the cycle starting point.

(2) After the axis has been infed by the amount "D", it retracts by the amount "DA" at a rapid

traverse rate.

This peck-feeding cycle is repeated until the programmed target point in the infeed axis

direction is reached.

(3) When an L word is specified in the program, the infeed axis returns to the cycle start point each

time total infeed amount in the repeated peck feeding cycles reaches "L".

(4) When the target point in the infeed axis direction is reached, dwell motion is activated for the

duration commanded in an E word. If no E word is specified, dwell motion is not performed.

After that, the axis returns to the cycle starting point level, and then a shift is executed in

another axis direction by the commanded amount "K" or "I" at a rapid traverse rate.

(5) This completes one grooving cycle. The steps (1) through (4) are repeated to machine the

desired groove.

(6) When the offset tool position (offset number specified in the same block) reaches or goes

beyond the target point in the X or Z axis direction during repetition of a grooving cycle with

shift, the target point of the shift operation is taken as the final target point of the cycle; the final

grooving cycle is performed at that position. When the axis reaches the target depth in the final

grooving cycle, the axes return to the starting point of the compound fixed cycle.

A Z coordinate must always be specified in the G74 block.

X

Z

Za

K

Zs

Xs

N0001

N0002

N0003

G00

G74

X

S

X

S

S

Z

S

Z

a

T

K

M

D

L

E

F