5238-E P-165

SECTION 7 FIXED CYCLES

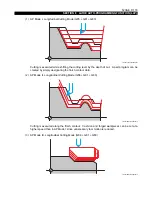

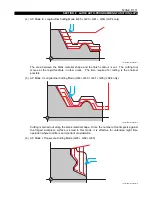

When cutting a thread having a width of 5 mm and 60 mm long as shown above, program as below

using G185 to call out the thread cutting fixed cycle.

LE33013R0300900520006

[Supplement]

LE33013R0300900520007

•

Command SA = 12 in the N103 block specifies the feedrate along the C-axis as 12 min

-1

.

•

The repeat function is not available for the thread cutting fixed cycles called by G185 through

G188.

•

In the thread cutting fixed cycle called for by G185 through G188, only the G95 feedrate mode

is selectable. Programming G94 in these modes results in alarm. In this mode, the feedrate of

the C-axis is referred to.

•

In the thread cutting cycles called by G185 through G188, only constant pitch thread can be cut.

•

In the G183 mode, an F code specifies thread pitch.

N099

N100

N101

N102

N103

N104

N105

N106

N107

N108

N109

N110

M05

M110

M15

T0505

SB=400

SA12

M12

M109

M02

G00

G095

G185

G180

G00

G95

X1000

X110

X95

X90

X85

X80

X1000

Z1000

Z120

Z60

Z1000

C0

F10

Continued from turning operation program

The spindle indexes to the 0

°

position.

After the end mill is positioned to X95

at the rapid feedrate, it starts rotating

in the leftward direction at

400 min

-1

.

The end mill is fed to Z60 at the

commanded feedrate, 10 mm/rev.

The end mill is returned to X110 at

the rapid feedrate.

The end mill is returned to Z120 at

the rapid feedrate.

The spindle indexes to the 0

°

position.

After the end mill is positioned at X90

at the rapid feedrate, the thread

cutting cycle is executed.

In the same way, the spindle indexes

and thread cutting cycle is executed

up to X85

In the same way, the thread cutting

cycle is executed at X80

G180 cancels the fixed cycle mode.

Command point

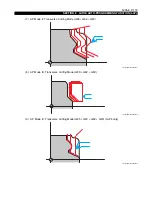

Example 4:

Tool No. : T0707

Program

zero

Tool

: ø5 end mill

80

100

A

B

C

C330

°

C0

°

C210

°

C90

°

75

45

20

15

100

80

40

SB = 1000 min

-1