5238-E P-81

SECTION 6 OFFSET FUNCTION

1-8-4. Behavior on Cancelation of the Tool Nose Radius Compensation Mode

G40 given with X- or Z-axis motion command

To cancel the tool nose radius compensation mode, the G40 code is used. It is essential to

understand the cutting tool movements that result from the cancelation of the compensation mode in

order to avoid unexpected trouble.

In the tool nose radius compensation mode, the tool path is generated so that the tool nose R is

always in contact with the programmed contour, but the axis position is controlled so that the tool tip

reference point traces the programmed contour when the tool nose radius compensation mode is

not active. Therefore, under- or over-cut often results when entering into or when canceling the tool

nose radius compensation mode.

LE33013R0300800110001

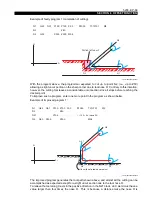

Cutting a contour comprising straight line segments as illustrated above is programmed as shown

below if the tool nose radius compensation mode is not active.

LE33013R0300800110002

With the commands above, the cutting tool moves along the path indicated by broken lines. That is,

for designated point N3 the tool center is positioned at point O3, and at point O4 for designated

point N4.

The uncut part parallel to straight line N3 - N4 is left. Therefore the tool nose radius compensation

function can be effectively used to cut such a contour accurately. See the programs on the following

pages.

•

When the tool nose R compensation cancel command is designated:

LE33013R0300800110003

Position left uncut

Overcut portion

X

+

Z

+

N4

N3

N2

N1

O4

O2

O1

O3

N2

N3

N4

Z60

F0.2

X130 Z20

N1

G01

N5

X300 Z300

G00

X100

X120

Z100

S1000

T010101

M03

N2

N3

N4

Z60

F0.2

X130 Z20

N1

G42

G01

N5

X300 Z300

G00

G40

X100

X120

Z100

S1000

T010101

M03