5238-E P-130

SECTION 7 FIXED CYCLES

7.

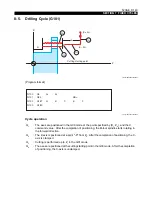

Tapping Compound Fixed Cycle

7-1.

Right-hand Tapping Cycle (G77)

[Function]

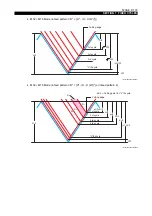

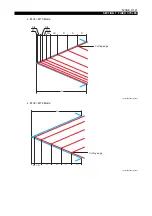

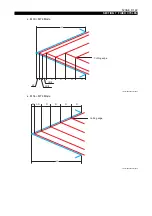

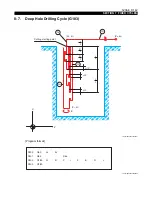

The compound cycle called out by G77 executes a tapping cycle like the one illustrated below.

LE33013R0300900240001

[Programming format]

G77 X__ Z__ K__ F__

Axis movements:

G77 : G code to call out tapping compound fixed cycle.

Specify this G code immediately after a sequence number (name).

X

: X coordinate of tapping cycle start point (target point)

Z

: Z coordinate of tapping cycle end point (target point)

K

: Rapid axis feedrate for axis feed from the cycle start point to the cutting start point

F

: Feedrate

Q

1

: The X-axis is positioned at the specified positioning target point (cycle start point) at a

rapid feedrate. In this positioning cycle, no Z-axis movement occurs and thus the turret

must be positioned at a point where it will not interfere with the workpiece during this

positioning before calling out the G77 cycle.

Q

2

: The spindle rotates clockwise at the speed applying before the G77 cycle is called.

Therefore, the required spindle speed must be specified before calling the G77 cycle.

If this compound fixed cycle is called without designating a spindle speed, axis infeed does

not occur since the spindle does not rotate and thus the cycle is halted.

Q

3

: The Z-axis is positioned at a position designated by a K word at a rapid feedrate.

Q

4

: Tapping is performed from the point reached in Q

3

to the depth specified by a Z word at a

specified feedrate (F).

Q

5

: The spindle stops once and then starts in the reverse direction at the same speed as used

in infeeding.

Q

6

: The Z-axis retracts to a point reached in the Q

4

cycle at a cutting feedrate.

Q

7

: The Z-axis retracts to a point reached in the Q

3

cycle at a rapid feedrate.

Q

2

Q

5

Q

6

Q

4

Q

3

Q

7

Q

1

Q

5

Q

2

X

Q

6

Q

4

Q

3

Q

7

Q

1

X

K

Z

K

Z

(Diagram)

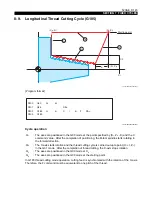

(Actual Example)