5238-E P-163

SECTION 7 FIXED CYCLES

[Supplement]

LE33013R0300900520003

When drilling the six equally spaced 10 mm dia. holes shown above, program as below using G183

for the deep hole drilling cycle.

LE33013R0300900520004

•

Tool rotation, and C-axis clamp and unclamp commands need not be designated in blocks

N103 through N106 as they are generated automatically.

•

In block N104, which calls out the drilling cycle at the second hole, program only the commands

differing from those specified in the previous block N103. In blocks N105 and N106, the same

programming concept applies.

•

S, M and T codes must not be programmed during fixed cycle mode operation.

Command point

Example 2:

Tool No. : T0303

Program

zero

Tool

: ø10 drill

80

A

B

F

E

C

D

C240

C120

C180

C0

C300

C60

50

φ

150

φ

ø120

SB = 400 min

-1

6 equally spaced holes,

ø10 mm

N099

N100

N101

N102

N103

N104

N105

N106

N107

N108

N109

N110

N111

N112

M05

M110

M15

T0303

SB=400

M12

M109

M02

G00

G94

G183

G180

G00

G95

X1000

X200

X40

X1000

Z1000

Z100

Z80

Z1000

C0

C60

C120

C180

C240

C300

I46

D10

E1

F40

Continued from turning operation program

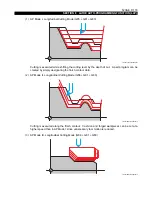

1. The spindle indexes to

the 0 position. After the

drill is positioned at

X80 mm at the rapid

feedrate, it starts rotating

at 400 min-1.

2. The drill is positioned at

X154 at the rapid

feedrate.

3. The drill is fed to X40

at the commanded

feedrate 40 mm/min.

4. The drill is returned to

X154 at the rapid

feedrate.

This

completes

drilling of hole A.

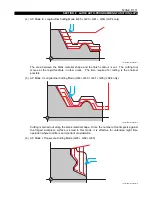

Drilling cycle at point B

Drilling cycle at point C

Drilling cycle at point D

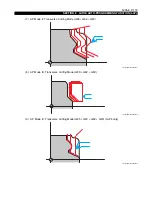

Drilling cycle at point E

Drilling cycle at point F