5238-E P-166

SECTION 7 FIXED CYCLES

When cutting a key way having a width of 5 mm and 20 mm long as shown above, program as

below using G190 to call out the key way cutting fixed cycle.

LE33013R0300900520008

[Supplement]

•

Tool rotation, and C-axis clamp and unclamp command in blocks N104 through N106 are

unnecessary as they are generated automatically.

•

In block N105, which calls out drilling cycle on the second hole, program only the commands

differing from those provided in the previous block N104. In blocks N106 and N107, the same

programming manner applies.

•

S, M, and T codes must not be programmed during fixed cycle mode operation.

N099

N100

N101

N102

N103

N104

N105

N106

N107

N108

N109

N110

M05

M110

M15

T0707

SB=

1000

M211

M213

M12

M109

M02

G00

G94

G190

G180

G00

G95

X1000

X200

X75

x45

X1000

Z1000

Z100

Z120

Z80

Z1000

C90

C210

C330

K15

D8 W0.2

E15

F30

Continued from turning operation program

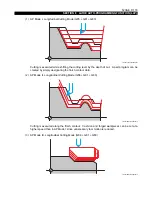

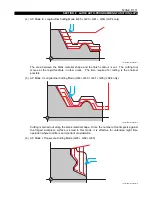

1. The spindle is indexed

to the 90

°

position.

The end mill is positioned

at the Z105 mm position

at the rapid feedrate and

the M-tool spindle starts

rotating in the CCW

direction at 1000 min-1.

2. The end mill cuts to the

Z97 mm position at

15

mm/min.

3. The end mill cuts to the

X45 mm position at

30

mm/min.

4. The end mill returns to

the Z105 mm position at

the rapid feedrate.

5. The end mill returns to

the X75 mm position at

the rapid feedrate

6. The end mill cuts to a

position 8 mm from the

previous infeed position.

7. Steps 3) - 6) are repeated

until the Z-axis reaches

the 80 mm position.

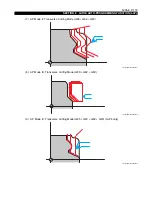

Machining of groove B

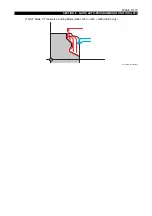

Machining of groove C