485

SELECTION

S

E

LECTION

3

3) Performing pre-excitation (LX signal and X13

signal) under torque control may start the motor

running at a low speed even when the start signal

(STF or STR) is not input. The motor may run also

at a low speed when the speed limit value = 0 with

a start command input. Perform pre-excitation

after making sure that there will be no problem in

safety if the motor runs.

4) Do not switch between the forward rotation

command (STF) and reverse rotation command

(STR) during operation under torque control.

Overcurrent trip (E.OC1 to 3) or opposite rotation

deceleration fault (E.11) occurs.

5) For the 0.4K to 3.7K, the speed deviation may

become large at 20Hz or less and torque may

become insufficient in the low speed range under

11Hz during continuous operation under Real

sensorless vector control. In this case, stop once

and accelerate again to improve.

6) When the inverter is likely to start during motor

coasting under Real sensorless vector control, set

to make frequency search of automatic restart

after instantaneous power failure valid [

Pr. 57

≠

9999, Pr. 162 = 10

].

7) The motor capacity should be equal to or one rank

lower than the inverter capacity. (note that the

capacity should be 0.4kW or more)

8) Single-motor operation (one motor run by one

inverter) should be performed.

(9) For selection of the vector control

For a load which requires control characteristics

equal to those of DC machines and torque control, fit

an optional FR-A7AP or FR-A7AL and select vector

control.

Vector control may be used under the following

restriction, conditions.

1) Even when motors (other manufacturer's motor,

SF-JRC, etc.) other than Mitsubishi standard

motor, high efficiency motor (SF-JR, SF-HR0.4kW

or more), Mitsubishi constant torque motor (SF-

JRCA, SF-HRCA 4-pole 0.4kW to 55kW), vector

control dedicated motor (SF-V5RU) are used,

using the offline auto tuning function runs the

motor with the optimum operating characteristics.

2) The motor capacity should be equal to or one rank

lower than the inverter capacity when using a

standard motor. (note that the capacity should be

0.4kW or more)

3) For vector control operation, the encoder should

be coupled on the same axis with the motor shaft

without any mechanical looseness. The speed

ratio should be 1:1.

4) Single-motor operation (one motor run by one

inverter) should be performed.

5) The wiring length from inverter to motor should be

within 30m.

(Perform offline auto tuning in the state where

wiring work is performed when the wiring length

exceeds 30m.)

6) For the vector control dedicated motor, the

inverter one or two ranks higher than the motor in

capacity needs to be selected depending on the

motor capacity.

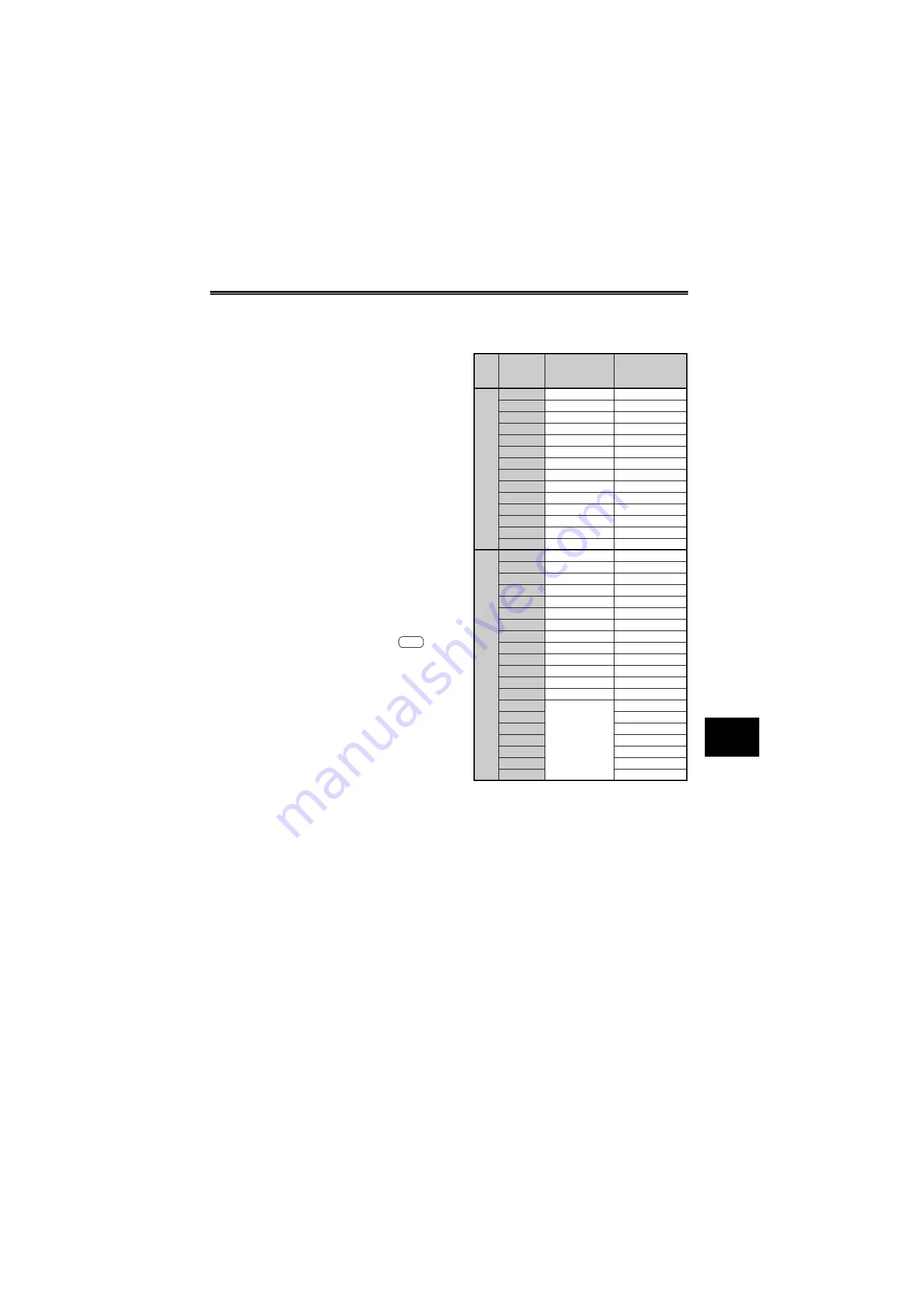

The table on the right indicates the combinations

of the SF-V5RU, SF-THY and inverter capacity.

A700

Vo

lt

a

g

e

Motor

Capacity

Motor Type

Inverter Type

200V

class

1.5kW

SF-V5RU1K

FR-A720-2.2K

2.2kW

SF-V5RU2K

FR-A720-3.7K

3.7kW

SF-V5RU3K

FR-A720-5.5K

5.5kW

SF-V5RU5K

FR-A720-7.5K

7.5kW

SF-V5RU7K

FR-A720-11K

11kW

SF-V5RU11K

FR-A720-15K

15kW

SF-V5RU15K

FR-A720-18.5K

18.5kW

SF-V5RU18K

FR-A720-22K

22kW

SF-V5RU22K

FR-A720-30K

30kW

SF-V5RU30K

FR-A720-37K

37kW

SF-V5RU37K

FR-A720-45K

45kW

SF-V5RU45K

FR-A720-55K

55kW

SF-V5RU55K

FR-A720-75K

75kW

SF-THY

FR-A720-90K

400V

class

1.5kW

SF-V5RUH1K

FR-A740-2.2K

2.2kW

SF-V5RUH2K

FR-A740-2.2K

3.7kW

SF-V5RUH3K

FR-A740-3.7K

5.5kW

SF-V5RUH5K

FR-A740-7.5K

7.5kW

SF-V5RUH7K

FR-A740-11K

11kW

SF-V5RUH11K

FR-A740-15K

15kW

SF-V5RUH15K

FR-A740-18.5K

18.5kW

SF-V5RUH18K

FR-A740-22K

22kW

SF-V5RUH22K

FR-A740-30K

30kW

SF-V5RUH30K

FR-A740-37K

37kW

SF-V5RUH37K

FR-A740-45K

45kW

SF-V5RUH45K

FR-A740-55K

55kW

SF-V5RUH55K

FR-A740-75K

75kW

SF-THY

FR-A740-90K

90kW

FR-A740-110K

110kW

FR-A740-132K

132kW

FR-A740-160K

160kW

FR-A740-185K

200kW

FR-A740-220K

250kW

FR-A740-280K

Summary of Contents for FR-A700 Series

Page 245: ...279 2 PARAMETER PARAMETER MEMO ...

Page 440: ...474 PARAMETER MEMO ...

Page 522: ...556 SELECTION MEMO ...