COPYRIGHT © 2001 CANON INC. CANON CLC1000/1000S/3100 REV.2 MAY 2001 PRINTED IN JAPAN (IMPRIME AU JAPON)

3-43

3. OPERATION AND TIMING

a.

Shading Correction

The output of the CCD is not always the same for the following reasons; this is true even if the original

has a uniform density:

• The sensitivities of the pixels of the CCD are not the same.

• The degree of transmission of the lens differs between the center and the periphery.

• The intensity of the scanning lamp differs between the middle and the edges.

• The scanning lamp deteriorates.

To compensate for the above discrepancies, the CLC1000 executes shading correction:

• Procedure of shading correction.

a)

The CCD reads the bar code under the

standard white plate and determines the

correction target value. (See Reference.)

Figure 3-307

b)

The CCD measures the light reflected by the

standard white plate and generates data

representing the measurement.

Figure 3-308

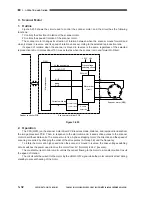

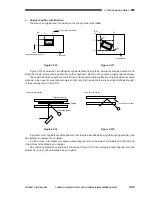

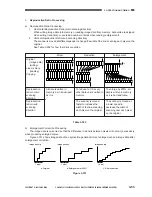

c)

The shading correction circuit compares the

measurement data (step b) against the target

value (step a) and stores the difference in

memory as the shading correction value.

The shading correction value is used to obtain

uniform data values when scanning originals.

Measurements are taken each time the Start

key is pressed.

Figure 3-309

Copyboard glass

Glass

Standard white plate

Bar code

Scanning lamp

Lens

CCD

Copyboard glass

Glass

Standard white plate

Bar code

Scanning lamp

Lens

CCD

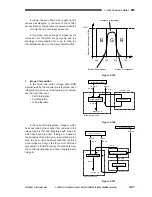

Standard white plate

0

CCD output

255

Target value

(TRGT)

Characteristics before correction

Original density

White

Characteristics after correction

Measurement data

Summary of Contents for Vizcam 1000

Page 12: ......

Page 30: ......

Page 44: ......

Page 86: ......

Page 254: ......

Page 372: ......

Page 374: ......

Page 418: ......

Page 438: ......

Page 442: ......

Page 754: ......

Page 764: ......

Page 766: ......

Page 840: ...0501GR PRINTED IN JAPAN IMPRIME AU JAPON This publication is printed on 100 reprocessed paper...