COPYRIGHT © 2001 CANON INC. CANON CLC1000/1000S/3100 REV.2 MAY 2001 PRINTED IN JAPAN (IMPRIME AU JAPON)

7-297

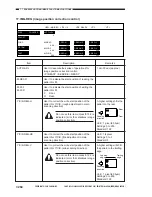

7. TROUBLESHOOTING IMAGE FAULTS/MALFUNCTIONS

Code

E004

E005

E006

E012

E013

E014

E015

E017

E018

Cause

Triac (short circuit)

• Cleaning web (inside fixing

assembly; taken up)

• Web length sensor (PS36; faulty)

• DC controller PCB (faulty)

• Fixing drawer connector (fault)

• Fixing lever switch (SW5; fault)

• DC controller PCB (fault)

• Drum drive system (overload)

• Drum motor (M21; error)

• DC controller PCB (faulty)

• Waste toner feeding motor (faulty)

• Waste toner feeding screw

(rotation fault)

• DC controller PCB (faulty)

• Fixing motor (M9; error)

• DC controller PCB (faulty)

• Pick-up motor (M10; faulty)

• DC controller PCB (faulty)

• Duplexing feeding motor (M19;

faulty)

• DC controller PCB (faulty)

• Polishing/oil removing motor

(M15; faulty)

• DC controller PCB (faulty)

Description

0001

The triac is ON after the CPU on the

DC controller PCB has turned ON the

fixing heater triac drive signal.

0002

The triac is ON after the microproces-

sor on the DC controller PCB has

turned OFF the triac drive signal for the

drum heater.

The cleaning web solenoid has turned ON 270

times after the web length sensor detected the

lever.

0001

The fixing drawer connector connec-

tion signal CONNECT goes ‘0’ when

the front cover is closed (i.e., the

drawer connector is disconnected).

0002

The fixing lever switch signal F-KBLK

goes ‘1’ when the front cover is closed

(i.e., the fixing knob is not set).

0001

The rotation speed of the motor has

deviated from a specific value for 0.1

sec or more.

0001

The rotation speed of the waste toner

feeding motor has deviated from a

specific value for 0.1 sec or more (PLL

signal ‘0’).

0002

The waste toner lock detection switch

(SW4) has been pressed for 0.1 sec or

more.

The rotation speed of the motor has deviated

from a specific value for 0.1 sec or more.

• The clock pulses of the pick-up motor

cannot be detected.

• The rotation speed of the motor has deviated

from a specific speed for 0.1 sec or more.

• The rotation speed of the duplexing feeding

motor has deviated from a specific value for

0.1 sec or more (PLL signal ‘0’).

• The rotation speed of the polishing/oil

removing motor has deviated from a specific

value for 0.1 sec or more.

Summary of Contents for Vizcam 1000

Page 12: ......

Page 30: ......

Page 44: ......

Page 86: ......

Page 254: ......

Page 372: ......

Page 374: ......

Page 418: ......

Page 438: ......

Page 442: ......

Page 754: ......

Page 764: ......

Page 766: ......

Page 840: ...0501GR PRINTED IN JAPAN IMPRIME AU JAPON This publication is printed on 100 reprocessed paper...