14.3 Motion Control

14-93

14.3.16 Rigid tap

YS 840DI system tapping function "Rigid Tap" is permitted with the interpolation control of

the spindle and the feed axis, which is different from the conventional system.

In this case, to lessen the synchronicity errors, the position loop gain of feed axis (generally

Z axis) and the position loop gain of spindle must be identical.

Therefore, when the rigid tap is enabled, the position loop gain POSCTRL_GAIN [1], dedi-

cated to the rigid tap, is used.

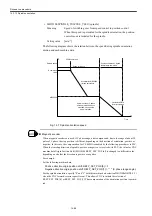

Setting the same values for loop gain of the spindle and the feed axis (see below) can reduce

the synchronicity errors during the rigid tapping.

For the detailed information of Rigid pap function, see the Programing Manual for Machin-

ing Center (NCSIE-SP02-20).

MD32200 POSCTRL_GAIN [1] (For each axis)

Meaning:

Position loop gain

Setting value: [1/s] (Sets the position loop gain in the unit specified with MD10230)

Note: With each axis MD32900 DYN_MATCH_ENABLE = 1, it is possi-

ble to set each axis conventional position loop gain MD32200 [0] to

be equal.

In this case. however, since the function is enabled for the axis for

which interpolation is enabled independently with Rigid Tap, you

must specify the individual spindle and feed axis separately when set-

ting the time constant for adjustment MD32910

DYN_MATCH_TIME.

The acc./dec. rate during Tapping motion is set to the lower value of acceleration setting values of

either the conventional cutting feed or the spindle orientation.

Also it is possible to improve accuracy by enabling the feedforward control when rigid tap is enabled.

See section 14.3.7.

INFO

Содержание CNC Series

Страница 1: ...Maintenance Manual Serviceman Handbook MANUAL No NCSIE SP02 19 Yaskawa Siemens CNC Series...

Страница 26: ...Part 1 Hardware...

Страница 38: ...System Configuration 1 2 3 Spindle motor designations 1 12...

Страница 58: ...Installing the control panels 2 3 5 Installing lightning surge absorbers 2 20...

Страница 62: ...Installing the motors 3 4...

Страница 84: ...Connection method 4 3 2 Setting the rotary switches on the inverters and servo units 4 22...

Страница 96: ...Part 2 Software...

Страница 102: ...Software configuration 6 6...

Страница 103: ...7 1 Chapter 7 Backup 7 1 How to archive 7 2 7 2 Network settings 7 7 7 2 1 YS 840DI settings 7 7 7 2 2 PC settings 7 14...

Страница 105: ...7 1 How to archive 7 3 3 Select the Workpieces folder 4 Click on Archive File which is one of the right side keys...

Страница 113: ...7 2 Network settings 7 11 8 Click on the radio button to the left of Specify an IP address...

Страница 121: ...7 2 Network settings 7 19...

Страница 122: ...Part 3 PLC...

Страница 154: ...Part 4 Setting up and maintenance...

Страница 160: ...Overview of System 10 1 2 Basic operation 10 6...

Страница 204: ...How to use Digital Operation 12 2 9 Setting the password setting for write prohibit 12 32...

Страница 327: ...Error and Troubleshooting 15 4...

Страница 328: ...15 1 Errors without Alarm Display and Troubleshooting 15 5...

Страница 329: ...Error and Troubleshooting 15 6...

Страница 343: ...Maintenance and Check 16 3 3 Setting up Initializing Absolute encoder 16 14...