4.2 Power on/off signals

4-17

• The brake release output signal to control the brake of a motor must come from the servo unit driv-

ing that motor.

• The UPS module must not be used to power other than those units shown in Fig. 4.1.

• Wire between the Alarm terminals and an I/O module as necessary.

• Interlock the BKX relay as necessary by externally adding an interlock signal to the brake release

output signal.

• It is the responsibility for the customer to provide the emergency stop switch and its wiring.

• It is the responsibility for the customer to provide the X121 connector (37-pin D-Sub female con-

nector) and related wiring.

• The SVMX, ESPX, and BKX relays must be 24 VDC miniature relays (preferably LY-2 from

OMRON).

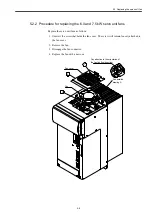

4.2.2 UPS module timer setting

The UPS module must have its timer set so that the 24 VDC power supply will be available

for a certain period even after a blackout occurs (to earn time necessary for memory data to

be transferred to a hard disk). The relationship between timer setting and covered period is

shown below. The covered period should be at least 85 seconds.

Fig. 4.2 UPS module timer setting

Position of the timer switch elements

1 means ON, 0 means OFF, and x means any position (irrelevant).

If switch element 1 is set to the OFF position, the UPS module supplies power as long as the

supplied voltage is above the low battery level.

INFO

5

1

0

0

0

0

0

15

1

0

0

0

0

1

25

1

0

0

0

1

0

35

1

0

0

0

1

0

45

1

0

0

1

0

1

55

1

0

0

1

0

0

65

1

0

0

1

1

1

75

1

0

0

1

1

0

85

1

0

1

0

0

1

95

1

0

1

0

0

0

105

1

0

1

0

1

1

115

1

0

1

0

1

0

125

1

0

1

1

0

1

135

1

0

1

1

0

0

145

1

0

1

1

1

1

155

1

0

1

1

1

0

165

1

1

0

0

0

1

175

1

1

0

0

0

0

185

1

1

0

0

1

1

195

1

1

0

0

1

0

205

1

1

0

1

0

1

215

1

1

0

1

0

0

225

1

1

0

1

1

1

235

1

1

0

1

1

0

245

1

1

1

0

0

1

255

1

1

1

0

0

0

265

1

1

1

0

1

1

275

1

1

1

0

1

0

285

1

1

1

1

0

1

295

1

1

1

1

0

0

305

1

1

1

1

1

1

315

1

1

1

1

1

0

max

0

x

x

x

x

x

Covered period

On

2

3

4

5

6

X 400

Содержание CNC Series

Страница 1: ...Maintenance Manual Serviceman Handbook MANUAL No NCSIE SP02 19 Yaskawa Siemens CNC Series...

Страница 26: ...Part 1 Hardware...

Страница 38: ...System Configuration 1 2 3 Spindle motor designations 1 12...

Страница 58: ...Installing the control panels 2 3 5 Installing lightning surge absorbers 2 20...

Страница 62: ...Installing the motors 3 4...

Страница 84: ...Connection method 4 3 2 Setting the rotary switches on the inverters and servo units 4 22...

Страница 96: ...Part 2 Software...

Страница 102: ...Software configuration 6 6...

Страница 103: ...7 1 Chapter 7 Backup 7 1 How to archive 7 2 7 2 Network settings 7 7 7 2 1 YS 840DI settings 7 7 7 2 2 PC settings 7 14...

Страница 105: ...7 1 How to archive 7 3 3 Select the Workpieces folder 4 Click on Archive File which is one of the right side keys...

Страница 113: ...7 2 Network settings 7 11 8 Click on the radio button to the left of Specify an IP address...

Страница 121: ...7 2 Network settings 7 19...

Страница 122: ...Part 3 PLC...

Страница 154: ...Part 4 Setting up and maintenance...

Страница 160: ...Overview of System 10 1 2 Basic operation 10 6...

Страница 204: ...How to use Digital Operation 12 2 9 Setting the password setting for write prohibit 12 32...

Страница 327: ...Error and Troubleshooting 15 4...

Страница 328: ...15 1 Errors without Alarm Display and Troubleshooting 15 5...

Страница 329: ...Error and Troubleshooting 15 6...

Страница 343: ...Maintenance and Check 16 3 3 Setting up Initializing Absolute encoder 16 14...