14.4 High-speed High-accuracy Cutting

14-97

14.4 High-speed High-accuracy Cutting

YS 840DI system High-speed High-accuracy Cutting function does not have any special high-

speed modes, such as conventional U-HSC function or G-HSC function, which are different

from general cutting modes. This High-speed High-accuracy Cutting function enables the con-

ventional cutting to provide machining as accurate as G-HSC function which employs the

multi-block look-ahead.

In addition, by adding the following functions to the conventional cutting feed, higher-speed,

higher-accuracy cutting is provided for micro-block program machining such as die machining.

• Block compression: Two or more blocks having accuracy less than setting tolerance are

compressed into a single linear or spline block. This allows high-speed processing for

micro-length block for die machining.

• Spline interpolation: Using some spline interpolation algorithms, linear blocks are con-

verted into spline curves so that smooth machining face can be permitted.

There is no particular conditions for maneuverability, especially for G code, since con-

ventional cutting feed function is used.

• Predictive control is always enabled with usual cutting feed.

• For details about the acc./dec. control setting, see Section 14.3.2.

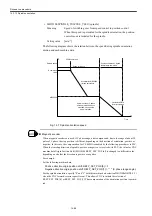

14.4.1 Multi-block look-ahead

To permit the feed speed control suitable for machining pattern, multi-block look-ahead is

enabled.

Parameters for the multi-block look-ahead are shown as followings.

• MD18360 EXT_PRG_BUFFER_SIZE

Meaning:

Definition for memory required for external memory operation

Setting value: 100Kbyte

• MD28060 IPO_BUFFER_SIZE

Meaning: IPO

buffer

size

(Definition for the number of blocks inside interpolation buffer)

Setting value: 2 to 300 blocks

Standard setting value: 100 blocks

• MD28070 NUM_BLOCKS_IN_PREP

Meaning:

Number of reserved blocks (Definition for the number of blocks

reserved)

Setting value: 2 minimum, maximum value depends on memory capacity

Standard setting value: 60 blocks

INFO

Содержание CNC Series

Страница 1: ...Maintenance Manual Serviceman Handbook MANUAL No NCSIE SP02 19 Yaskawa Siemens CNC Series...

Страница 26: ...Part 1 Hardware...

Страница 38: ...System Configuration 1 2 3 Spindle motor designations 1 12...

Страница 58: ...Installing the control panels 2 3 5 Installing lightning surge absorbers 2 20...

Страница 62: ...Installing the motors 3 4...

Страница 84: ...Connection method 4 3 2 Setting the rotary switches on the inverters and servo units 4 22...

Страница 96: ...Part 2 Software...

Страница 102: ...Software configuration 6 6...

Страница 103: ...7 1 Chapter 7 Backup 7 1 How to archive 7 2 7 2 Network settings 7 7 7 2 1 YS 840DI settings 7 7 7 2 2 PC settings 7 14...

Страница 105: ...7 1 How to archive 7 3 3 Select the Workpieces folder 4 Click on Archive File which is one of the right side keys...

Страница 113: ...7 2 Network settings 7 11 8 Click on the radio button to the left of Specify an IP address...

Страница 121: ...7 2 Network settings 7 19...

Страница 122: ...Part 3 PLC...

Страница 154: ...Part 4 Setting up and maintenance...

Страница 160: ...Overview of System 10 1 2 Basic operation 10 6...

Страница 204: ...How to use Digital Operation 12 2 9 Setting the password setting for write prohibit 12 32...

Страница 327: ...Error and Troubleshooting 15 4...

Страница 328: ...15 1 Errors without Alarm Display and Troubleshooting 15 5...

Страница 329: ...Error and Troubleshooting 15 6...

Страница 343: ...Maintenance and Check 16 3 3 Setting up Initializing Absolute encoder 16 14...