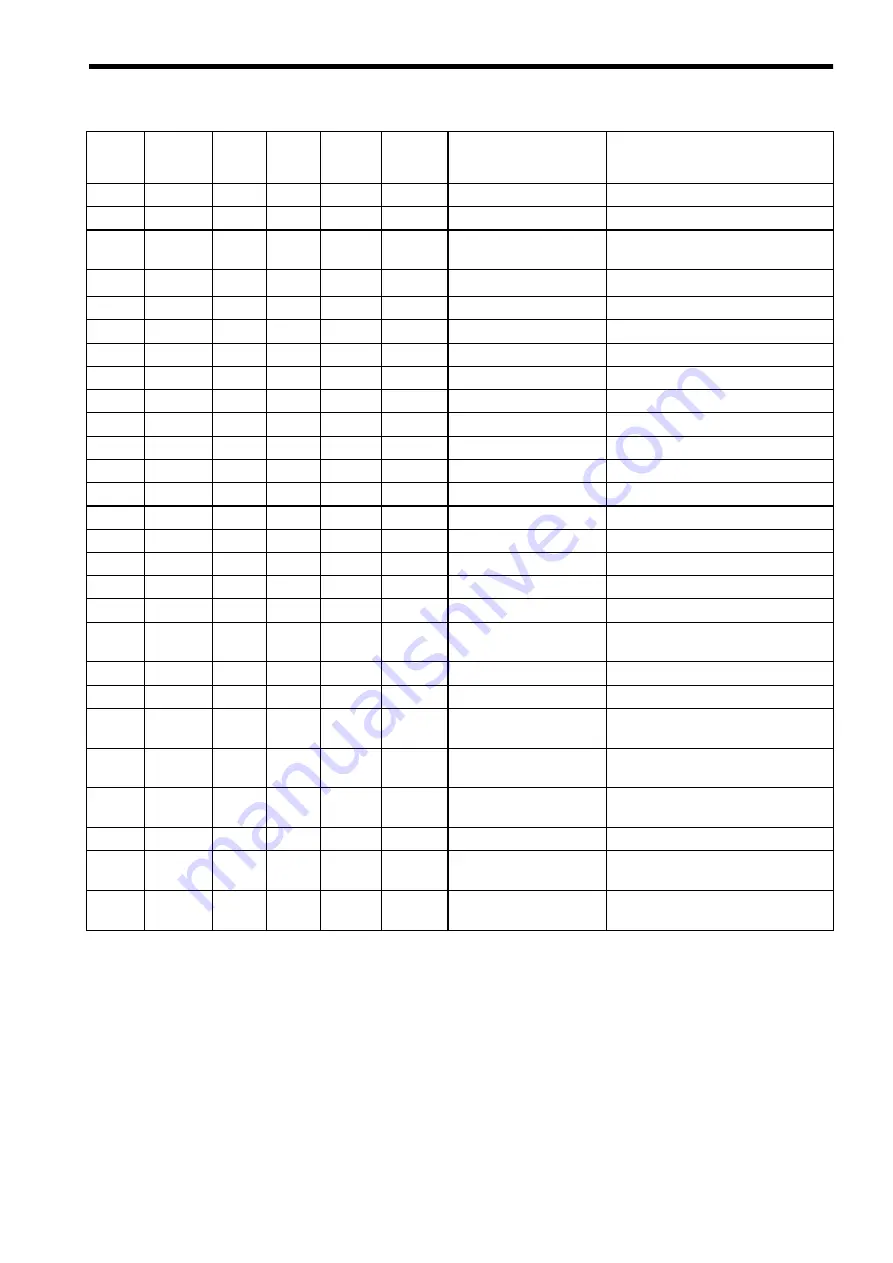

Appendix A Parameters

A-7

3424

Pn504

7

1

250

None

Near Window

NEAR signal width

3425

Pn505

1024

1

32767

None

Overflow Level

Overflow level

3426

Pn506

0

0

50

10ms

Delay from BrkSig to

SvOff

Brake command-to-Servo off delay

time

3427

Pn507

100

0

10000

min

-1

Spd on Brake Sig Out

Brake command output speed level

3428

Pn508

50

10

100

10ms

Sv Off Brk Sig Wait Time

Servo off-to-Brake command wait time

3429

Pn509

20

20

1000

None

Reserved

Reserved constant (Do not use)

3430

Pn50A

0x8880 0x7000

0x8FFF

None

Reserved

Reserved constant (Do not use)

3431

Pn50B

0x8888 0x7000

0x8FFF

None

Reserved

Reserved constant (Do not use)

3432

Pn50C

0x8888 0x0000

0xFFFF

None

Reserved

Reserved constant (Do not use)

3433

Pn50D

0x8888 0x0000

0xFFFF

None

Reserved

Reserved constant (Do not use)

3434

Pn50E

0x0000 0x0000

0xFFFF

None

Reserved

Reserved constant (Do not use)

3435

Pn50F

0x0000 0x0000

0xFFFF

None

Reserved

Reserved constant (Do not use)

3436

Pn510

0x0000 0x0000

0xFFFF

None

Reserved

Reserved constant (Do not use)

3437

Pn511

0x8888 0x0000

0xFFFF

None

Reserved

Reserved constant (Do not use)

3438

Pn512

0x0000 0x0000

0xFFFF

None

Reserved

Reserved constant (Do not use)

3439

Pn513

7

0

250

None

Position Window 1

1st positioning completion width

3440

Pn514

7

0

250

None

Position Window 2

2nd positioning completion width

3441

Pn515

7

0

250

None

Position Window 3

3rd positioning completion width

3442

Pn516

500

0

10000

ms

Emergency Stop Wait

Time

Emergency stop wait time

3470

Pn600

0

0

65535

None

Reserved

Reserved constant (Do not use)

3471

Pn601

0

0

65535

None

Reserved

Reserved constant (Do not use)

3472

Pn602

0x0000 0x0000

0x0001

None

Ext PG Power Switch

External PG power high/low voltage

switch

3508

Pn808

0x0000 0x0000

0xFFFF

None

Abs PG Zero Point Offs

LW

Absolute PG zero point offset

(Lower word)

3509

Pn809

0x0000 0x0000

0xFFFF

None

Abs PG Zero Point Offs

HW

Absolute PG zero point offset

(Upper word)

3510

Pn80A

100

1

65535

None

Const Linear Accel 1

1st-stage linear acceleration constant

3527

Pn81B

0x0000 0x0000

0x1111

None

Mask MFC BankSel 0 3

Model following control mask when

Loop gain bank 0-3 is selected.

3528

Pn81C

500

0

30000

ms

Tactor Off Delay Time

Time from tactor-off ready to actual

tactor-off.

CNC

parameter

number

Drive

parameter

number

Initial

value

Lower

limit

Upper

limit

Unit

Display name

Description

Содержание CNC Series

Страница 1: ...Maintenance Manual Serviceman Handbook MANUAL No NCSIE SP02 19 Yaskawa Siemens CNC Series...

Страница 26: ...Part 1 Hardware...

Страница 38: ...System Configuration 1 2 3 Spindle motor designations 1 12...

Страница 58: ...Installing the control panels 2 3 5 Installing lightning surge absorbers 2 20...

Страница 62: ...Installing the motors 3 4...

Страница 84: ...Connection method 4 3 2 Setting the rotary switches on the inverters and servo units 4 22...

Страница 96: ...Part 2 Software...

Страница 102: ...Software configuration 6 6...

Страница 103: ...7 1 Chapter 7 Backup 7 1 How to archive 7 2 7 2 Network settings 7 7 7 2 1 YS 840DI settings 7 7 7 2 2 PC settings 7 14...

Страница 105: ...7 1 How to archive 7 3 3 Select the Workpieces folder 4 Click on Archive File which is one of the right side keys...

Страница 113: ...7 2 Network settings 7 11 8 Click on the radio button to the left of Specify an IP address...

Страница 121: ...7 2 Network settings 7 19...

Страница 122: ...Part 3 PLC...

Страница 154: ...Part 4 Setting up and maintenance...

Страница 160: ...Overview of System 10 1 2 Basic operation 10 6...

Страница 204: ...How to use Digital Operation 12 2 9 Setting the password setting for write prohibit 12 32...

Страница 327: ...Error and Troubleshooting 15 4...

Страница 328: ...15 1 Errors without Alarm Display and Troubleshooting 15 5...

Страница 329: ...Error and Troubleshooting 15 6...

Страница 343: ...Maintenance and Check 16 3 3 Setting up Initializing Absolute encoder 16 14...