12.1 Basic operation

12-9

The user constant numbers which is not defined will be skipped during the operation.

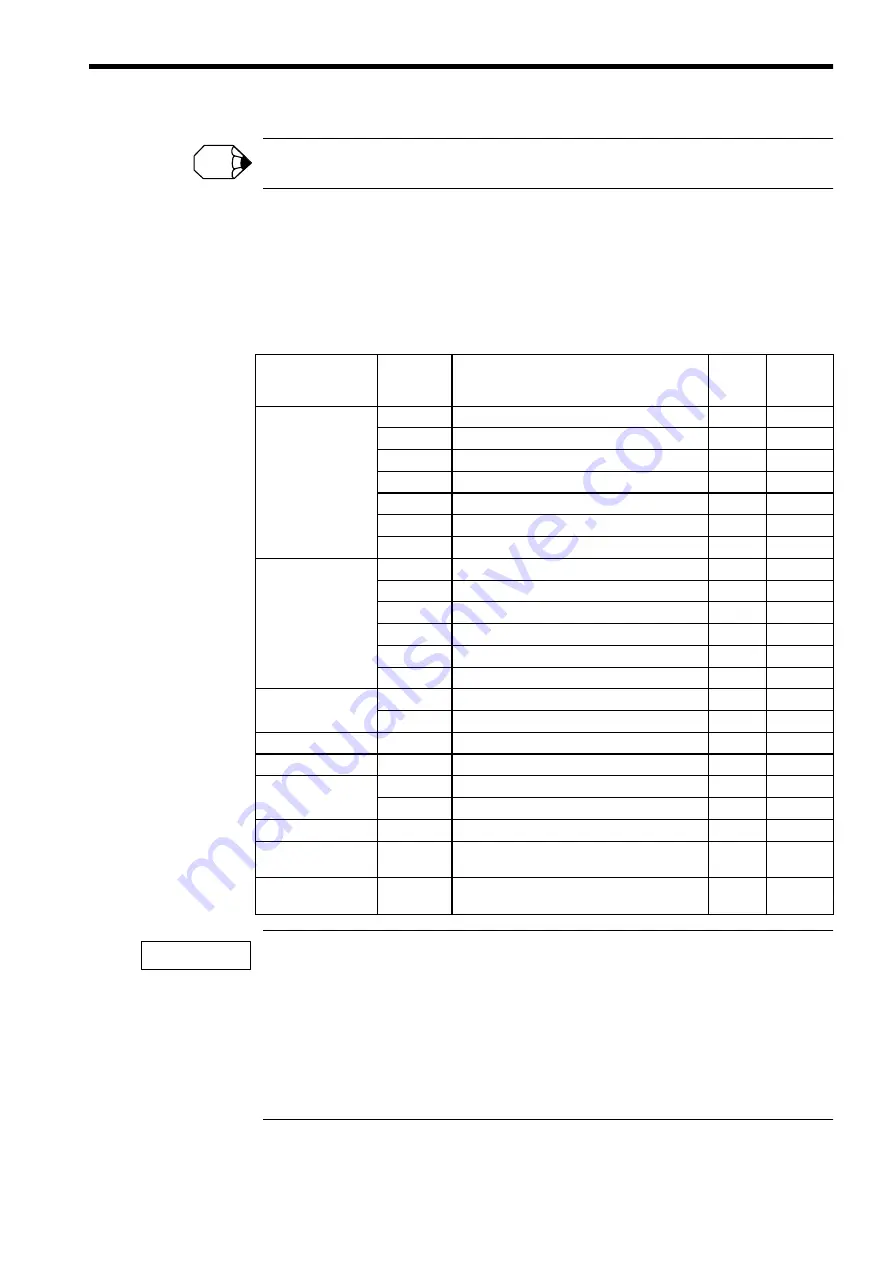

User constant for function selection

Type of function selection user constant

The following table lists the user constants used for selecting each function of SERVO-

PACK.

If you change the user constant that has a "

○

" in the remark column, you must cut off and then turn

on (or reclose) the power supply of both the main circuit and the control source in order to enable the

function of which setting you have just changed.

Also, some of the user constants that have an asterisk (*), such as Pn10B.1, Pn10B.3, Pn110.0,

Pn110.3, Pn127.0, and Pn408.2 requires the "reclosing the power supply" as shown above. On the con-

trary, Pn127.1 (Speed FF smoothing selection), Pn408.0 (1st stage notch filter selection) and Pn408.1

(2nd notch filter selection) can function on-line. Therefore they do not require the "recloseing the

power supply".

INFO

Type

User

constant

number

Name

Preset

value

Remarks

Constant for function

selection

Pn000

Function selection basic switch

0070

○

Pn001

Function selection application switch 1

0000

○

Pn002

Function selection application switch 2

0000

○

Pn003

Function selection application switch 3

0002

Pn004

Function selection application switch 4

0000

○

Pn005

Function selection application switch 5

0000

○

Pn006

Function selection application switch 6

0000

○

Constant for servo

gain

Pn10B

Gain application switch

0004

*

Pn110

On-line automatic tuning switch

0012

*

Pn126

Function switch 1

0000

○

Pn127

Function switch 2

0000

*

Pn128

Loop gain bank switch

0000

○

Pn131

Predictive control parameter switch

0000

○

Constant for Position

control

Pn200

Position control instruction type selection switch

0100

○

Pn207

Position control function switch

0000

○

Constant for toque

Pn408

Torque function switch

0000

*

Communication

Pn800

Communication control

0000

Constant for

sequence

Pn801

Soft limit selection switch

0000

Pn802

Command mask

0000

○

Monitor

Pn813

Option monitor

0010

Command

supplement

Pn816

Return to reference point direction

0000

Control function

selection

Pn81B

Model following control mask

0000

IMPORTANT

Содержание CNC Series

Страница 1: ...Maintenance Manual Serviceman Handbook MANUAL No NCSIE SP02 19 Yaskawa Siemens CNC Series...

Страница 26: ...Part 1 Hardware...

Страница 38: ...System Configuration 1 2 3 Spindle motor designations 1 12...

Страница 58: ...Installing the control panels 2 3 5 Installing lightning surge absorbers 2 20...

Страница 62: ...Installing the motors 3 4...

Страница 84: ...Connection method 4 3 2 Setting the rotary switches on the inverters and servo units 4 22...

Страница 96: ...Part 2 Software...

Страница 102: ...Software configuration 6 6...

Страница 103: ...7 1 Chapter 7 Backup 7 1 How to archive 7 2 7 2 Network settings 7 7 7 2 1 YS 840DI settings 7 7 7 2 2 PC settings 7 14...

Страница 105: ...7 1 How to archive 7 3 3 Select the Workpieces folder 4 Click on Archive File which is one of the right side keys...

Страница 113: ...7 2 Network settings 7 11 8 Click on the radio button to the left of Specify an IP address...

Страница 121: ...7 2 Network settings 7 19...

Страница 122: ...Part 3 PLC...

Страница 154: ...Part 4 Setting up and maintenance...

Страница 160: ...Overview of System 10 1 2 Basic operation 10 6...

Страница 204: ...How to use Digital Operation 12 2 9 Setting the password setting for write prohibit 12 32...

Страница 327: ...Error and Troubleshooting 15 4...

Страница 328: ...15 1 Errors without Alarm Display and Troubleshooting 15 5...

Страница 329: ...Error and Troubleshooting 15 6...

Страница 343: ...Maintenance and Check 16 3 3 Setting up Initializing Absolute encoder 16 14...