Drive set-up procedure

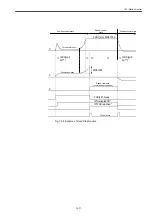

14.3.5 Return to reference point

14-70

• MD34060 REFP_MAX_MARKER_DIST [1] (For each axis)

Meaning:

C-phase searching maximum distance (separately mounted encoder)

Setting value: [mm] or [deg]

• MD34070 REFP_VERO_POS (For each axis)

Meaning:

Return to reference point speed

(return speed from the C-phase to the origin)

Setting value: [mm/min] or [min

-1

]

• MD34080 REFP_MOVE_DIST [0] (For each axis)

Meaning:

Return to reference point distance (distance from C phase to the origin)

(motor encoder)

Setting value: [mm] or [deg]

Note: Setting a negative value enables the motion to orient to the direction

opposite to the setting with MD34050.

• MD34080 REFP_MOVE_DIST [1] (For each axis)

Meaning:

Return to reference point distance (distance from C phase to the origin)

(separately mounted encoder)

Setting value: [mm] or [deg]

Note: Setting a negative value enables the motion to orient to the direction

opposite to the setting with MD34050.

• MD34090 REFP_MOVE_DIST_CORR [0] (For each axis)

Meaning:

Return to reference point distance offset (motor encoder)

Setting value: [mm] or [deg]

Note: When the absolute value detection function is used, the origin setting

value is written into this parameter.

• MD34090 REFP_MOVE_DIST_CORR [1] (For each axis)

Meaning:

Return to reference point distance offset (separately mounted encoder)

Setting value: [mm] or [deg]

Note: When the absolute value detection function is used, the origin setting

value is written into this parameter.

• MD34092 REFP_CAM_SHIFT [0] (For each axis)

Meaning:

Origin dog range shift (motor encoder)

When the origin dog is so close to C phase, the dog range is virtually

expanded with this machine data to prevent from detecting C phase fol-

lowing the dog.

Setting value: [mm] or [deg]

• MD34092 REFP_CAM_SHIFT [1] (For each axis)

Meaning:

Origin dog range shift (separately mounted encoder)

When the origin dog is so close to C phase, the dog range is virtually

expanded with this machine data to prevent from detecting C phase fol-

lowing the dog.

Setting value: [mm] or [deg]

Содержание CNC Series

Страница 1: ...Maintenance Manual Serviceman Handbook MANUAL No NCSIE SP02 19 Yaskawa Siemens CNC Series...

Страница 26: ...Part 1 Hardware...

Страница 38: ...System Configuration 1 2 3 Spindle motor designations 1 12...

Страница 58: ...Installing the control panels 2 3 5 Installing lightning surge absorbers 2 20...

Страница 62: ...Installing the motors 3 4...

Страница 84: ...Connection method 4 3 2 Setting the rotary switches on the inverters and servo units 4 22...

Страница 96: ...Part 2 Software...

Страница 102: ...Software configuration 6 6...

Страница 103: ...7 1 Chapter 7 Backup 7 1 How to archive 7 2 7 2 Network settings 7 7 7 2 1 YS 840DI settings 7 7 7 2 2 PC settings 7 14...

Страница 105: ...7 1 How to archive 7 3 3 Select the Workpieces folder 4 Click on Archive File which is one of the right side keys...

Страница 113: ...7 2 Network settings 7 11 8 Click on the radio button to the left of Specify an IP address...

Страница 121: ...7 2 Network settings 7 19...

Страница 122: ...Part 3 PLC...

Страница 154: ...Part 4 Setting up and maintenance...

Страница 160: ...Overview of System 10 1 2 Basic operation 10 6...

Страница 204: ...How to use Digital Operation 12 2 9 Setting the password setting for write prohibit 12 32...

Страница 327: ...Error and Troubleshooting 15 4...

Страница 328: ...15 1 Errors without Alarm Display and Troubleshooting 15 5...

Страница 329: ...Error and Troubleshooting 15 6...

Страница 343: ...Maintenance and Check 16 3 3 Setting up Initializing Absolute encoder 16 14...