10.9 Peripheral Devices and Options

SIEPYEUOQ2A01G AC Drive Q2A Technical Manual

407

10.9

Peripheral Devices and Options

This chapter shows the available peripheral devices and options for the drive.

•

Selection: Refer to the drive catalog for information about available products.

•

Installation and wiring: Refer to the instruction manual for each option.

◆

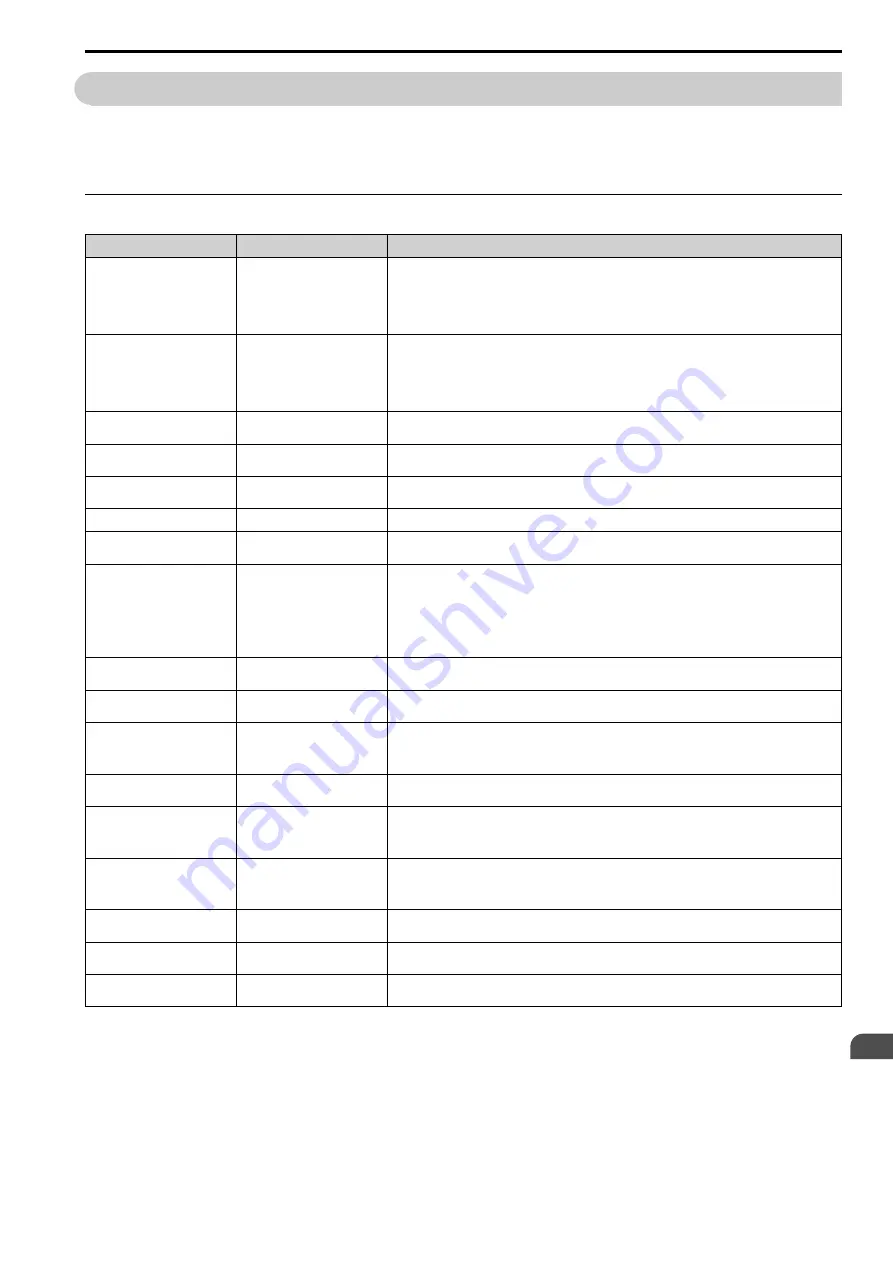

Main Circuit Options

Name

Model

Purpose

DC Reactor

UZDA series

To improve the drive input power factor.

•

To prevent damage to the drive when the power supply capacity is large. You must only use this option

when the power supply capacity is more than 600 kVA.

•

To decrease harmonic current.

•

To improve the power supply total power factor.

AC Reactor

UZBA series

To improve the drive input power factor.

•

To prevent damage to the drive when the power supply capacity is large. You must only use this option

when the power supply capacity is more than 600 kVA.

•

To decrease harmonic current.

•

To improve the power supply total power factor.

Braking Resistor

ERF-150WJ Series

To decrease the regenerative energy of the motor and decrease the deceleration time (duty cycle of 3%

ED). You must also use the installation attachment.

Braking Resistor with Fuse

CF120-B579 Series

To decrease the regenerative energy of the motor and decrease the deceleration time (duty cycle of 3%

ED). You must also use the installation attachment.

Braking Resistor Unit

LKEB series

To decrease the regenerative energy of the motor and decrease the deceleration time (duty cycle of 10%

ED). The unit contains a thermal overload relay.

Braking Unit

CDBR series

Use with a braking resistor unit to decrease motor deceleration times.

Molded-Case Circuit Breaker

(MCCB)

NF series

To prevent short circuit damage to the power supply system and provide overload protection for wiring.

Residual Current Monitor/

Detector (RCM/RCD)

NV and NS series

To prevent short circuit damage to the power supply system, provide overload protection for wiring,

prevent electrical shock, and provide ground fault protection against earth leakage fires.

Note:

•

You can use a molded-case circuit breaker as a replacement for an RCM/RCD that is upstream in the

power supply system.

•

When you use a high frequency RCM/RCD at the power input side of the drive, make sure that each

drive has a minimum cumulative sensitivity amperage of 30 mA.

Input Side Magnetic Contactor

(MC)

SC series

To prevent burn damage when connecting a braking resistor. This option fully opens the circuit between

the power supply and drive.

Surge Protective Device

400 V class: RFN3AL-504KD

To absorb open/close surges from the magnetic contactor and control relay. You must connect this option

to magnetic contactors, control relays, magnetic valves, or magnetic brake coils.

Zero-Phase Reactor

F6045GB

F11080GB

F200160PB

To decrease wiring noise. You can use this option on the input side and the output side of the drive.

Note:

Install this option around the drive input power system and as near to the drive as possible.

Fuse

Fuse Holder

400 V class: CR6L series, CS5F

series, or FWH series

To prevent part failure, we recommend that you connect a fuse to the input side of the drive.

Input Side Noise Filter

LNFB, LNFD, and FN series

To decrease wiring noise.

Note:

Install this option around the drive input power system and as near to the drive as possible.

Output Side Noise Filter

LF series

To decrease wiring noise.

Note:

Install this option around the drive input power system and as near to the drive as possible.

Capacitor-Type Noise Filter

3XYG 1003

To decrease wiring noise. You must only use this option around the drive input power system. Do not

connect this option to the output side.

Momentary Power Loss Recovery

Unit

400 V class: P0020

To make sure that the drive has power during the momentary power loss ride-thru time (2 seconds).

Low-Voltage Manual Load

Switch

“

AICUT

”

LB series

PM motors act as generators when coasting to provide voltage to terminals. Install this option to prevent

electric shock.

Содержание Q2A

Страница 2: ...This Page Intentionally Blank 2 SIEPYEUOQ2A01G AC Drive Q2A Technical Manual...

Страница 12: ...12 SIEPYEUOQ2A01G AC Drive Q2A Technical Manual...

Страница 18: ...i 2 Legal Information 18 SIEPYEUOQ2A01G AC Drive Q2A Technical Manual...

Страница 28: ...1 2 Features and Advantages of Control Methods 28 SIEPYEUOQ2A01G AC Drive Q2A Technical Manual...

Страница 64: ...2 9 Installation Methods 64 SIEPYEUOQ2A01G AC Drive Q2A Technical Manual...

Страница 166: ...4 9 Test Run Checklist 166 SIEPYEUOQ2A01G AC Drive Q2A Technical Manual...

Страница 172: ...5 2 European Standards 172 SIEPYEUOQ2A01G AC Drive Q2A Technical Manual...

Страница 173: ...Standards Compliance 5 5 2 European Standards SIEPYEUOQ2A01G AC Drive Q2A Technical Manual 173...

Страница 174: ...5 2 European Standards 174 SIEPYEUOQ2A01G AC Drive Q2A Technical Manual...

Страница 175: ...Standards Compliance 5 5 2 European Standards SIEPYEUOQ2A01G AC Drive Q2A Technical Manual 175...

Страница 176: ...5 2 European Standards 176 SIEPYEUOQ2A01G AC Drive Q2A Technical Manual...

Страница 258: ...6 2 Modbus Communications 258 SIEPYEUOQ2A01G AC Drive Q2A Technical Manual...

Страница 356: ...8 7 Storage Guidelines 356 SIEPYEUOQ2A01G AC Drive Q2A Technical Manual...

Страница 357: ...SIEPYEUOQ2A01G AC Drive Q2A Technical Manual 357 9 Disposal 9 1 Safety Precautions 358 9 2 Disposal Instructions 359...

Страница 360: ...9 2 Disposal Instructions 360 SIEPYEUOQ2A01G AC Drive Q2A Technical Manual...

Страница 526: ...11 20 Parameters Changed by PM Motor Code Selection 526 SIEPYEUOQ2A01G AC Drive Q2A Technical Manual...