282

SIEPYEUOQ2A01G AC Drive Q2A Technical Manual

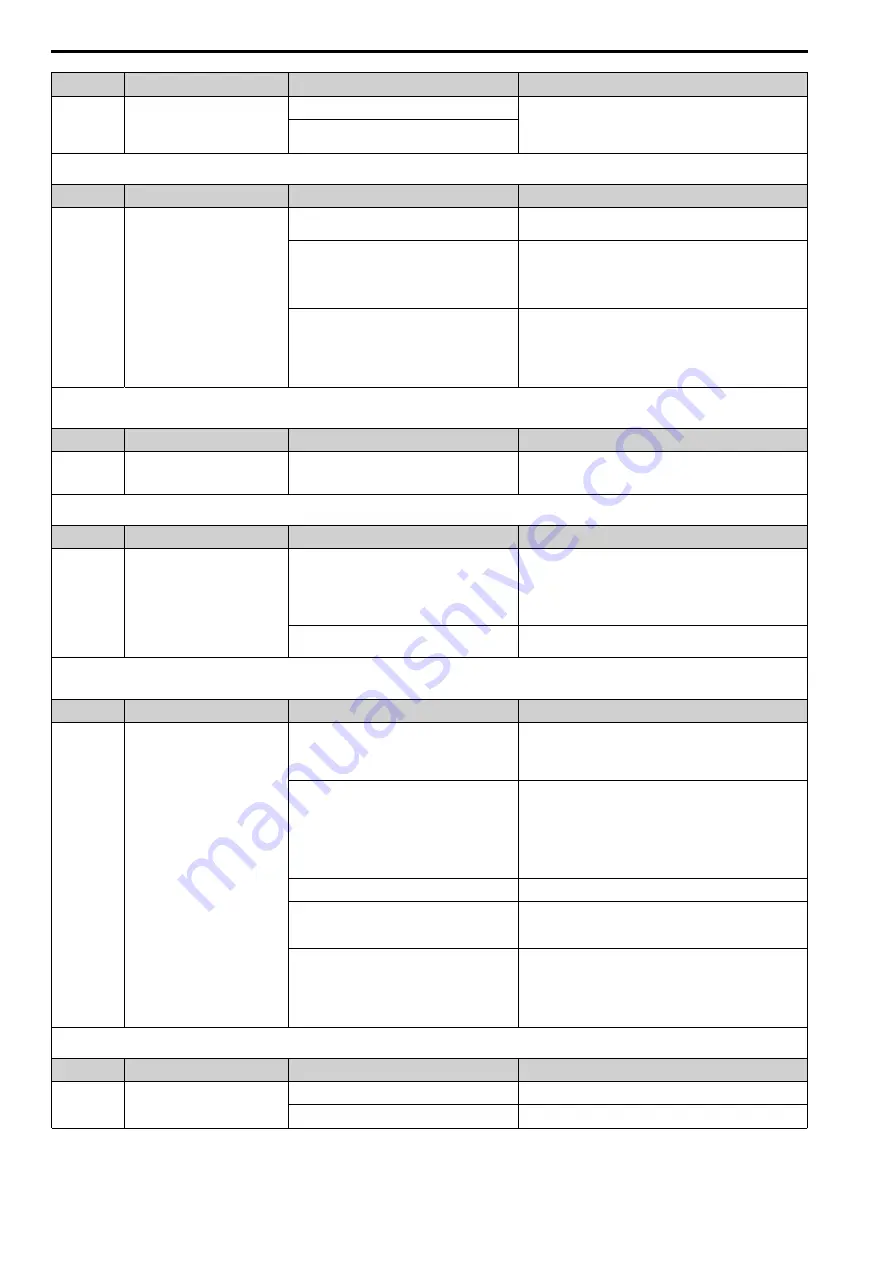

Code

Name

Causes

Possible Solutions

rr

Dynamic Braking Transistor Fault

The drive control circuit is damaged.

There is a malfunction in the internal braking

transistor of the drive.

•

Re-energize the drive.

•

If the fault stays, replace the control board or the drive. For

information about replacing the control board, contact the

manufacturer or your nearest sales representative.

Note:

Do a Fault Reset to clear the fault.

Code

Name

Causes

Possible Solutions

SC

Short Circuit/IGBT Failure

Overheating caused damage to the motor or the

motor insulation is not satisfactory.

Measure the motor insulation resistance, and replace the motor if

there is electrical conduction or unserviceable insulation.

The motor main circuit cable is contacting ground

to make a short circuit.

•

Examine the motor main circuit cable for damage, and repair

short circuits.

•

Measure the resistance between the motor main circuit cable

and the ground terminal. If there is electrical conduction,

replace the cable.

A short circuit or ground fault on the drive output

side caused damage to the output transistor of the

drive.

•

Make sure that there is not a short circuit in terminal B1 and

terminals U/T1, V/T2, and W/T3. Make sure that there is not a

short circuit in terminals - and terminals U/T1, V/T2, and W/

T3.

•

If there is a short circuit, contact the manufacturer or your

nearest sales representative.

Note:

•

The drive detects this error if there is a short circuit or ground fault on the drive output side, or an IGBT failure.

•

Do a Fault Reset to clear the fault.

Code

Name

Causes

Possible Solutions

SCF

Safety Circuit Fault

The safety circuit is broken.

Replace the control board or the drive. For information about

replacing the control board, contact the manufacturer or your

nearest sales representative.

Note:

Do a Fault Reset to clear the fault.

Code

Name

Causes

Possible Solutions

SEr

Speed Search Retries Exceeded

The speed search-related parameters are set

incorrectly.

•

Decrease the value set in

b3-10 [Speed Det Gain for

Estimation]

.

•

Increase the value set in

b3-17 [Speed Retry Current Level]

.

•

Increase the value set in

b3-18 [Speed Retry Delay]

.

•

Do Auto-Tuning again.

The motor is coasting in the opposite direction of

the Run command.

Set

b3-14 = 1 [Speed Bi-Directional Search = Enabled]

.

Note:

•

The drive detects this error if the number of speed search restarts is more than the value set in

b3-19 [Speed Retry Times]

.

•

Do a Fault Reset to clear the fault.

Code

Name

Causes

Possible Solutions

STPo

Motor Step-Out Detected

The motor code is set incorrectly for PM Control

Methods.

•

Enter the correct motor code to

E5-01 [PM Mot Code

Selection]

as specified by the PM motor.

•

For specialized motors, refer to the motor test report and set

E5-xx

correctly.

The load is too heavy.

•

Increase the value set in

n8-55 [Load Inertia]

.

•

Increase the value set in

n8-51 [Ac/Dec Pull-In Current]

. If the

drive detects

STPo

during deceleration when increasing the

value set in

n8-51

, set the value of

n8-79 [Pull-In

Curr@Deceleration]

lower than

n8-51

.

•

Decrease the load.

•

Replace the drive and motor with larger capacity models.

The load inertia is too heavy.

Increase the value set in

n8-55

.

The acceleration/deceleration times are too short.

•

Increase the acceleration/deceleration times set in

C1-01 to

C1-08 [Accel Time 1 to Decel Time 4]

.

•

Increase the value set in

C2-01 [Jerk@Start of Accel]

.

Speed response is too slow.

•

Increase the value set in

n8-55

.

•

If

STPo

occurs in Normal Duty mode when

A1-02 = 6

[Control Method = PM AOLVector]

, increase the value set in

n8-11 [Observ.Calc Gain2]

in increments of 10. If

STPo

occurs when starting a motor, decrease the value set in

n8-11

in

increments of 10.

Note:

Do a Fault Reset to clear the fault.

Code

Name

Causes

Possible Solutions

SvE

Zero Servo Fault

The value set in the torque limit is too small.

Adjust torque limit-related parameters

L7-01 to L7-04

.

The load torque is too large.

Decrease the load torque.

Содержание Q2A

Страница 2: ...This Page Intentionally Blank 2 SIEPYEUOQ2A01G AC Drive Q2A Technical Manual...

Страница 12: ...12 SIEPYEUOQ2A01G AC Drive Q2A Technical Manual...

Страница 18: ...i 2 Legal Information 18 SIEPYEUOQ2A01G AC Drive Q2A Technical Manual...

Страница 28: ...1 2 Features and Advantages of Control Methods 28 SIEPYEUOQ2A01G AC Drive Q2A Technical Manual...

Страница 64: ...2 9 Installation Methods 64 SIEPYEUOQ2A01G AC Drive Q2A Technical Manual...

Страница 166: ...4 9 Test Run Checklist 166 SIEPYEUOQ2A01G AC Drive Q2A Technical Manual...

Страница 172: ...5 2 European Standards 172 SIEPYEUOQ2A01G AC Drive Q2A Technical Manual...

Страница 173: ...Standards Compliance 5 5 2 European Standards SIEPYEUOQ2A01G AC Drive Q2A Technical Manual 173...

Страница 174: ...5 2 European Standards 174 SIEPYEUOQ2A01G AC Drive Q2A Technical Manual...

Страница 175: ...Standards Compliance 5 5 2 European Standards SIEPYEUOQ2A01G AC Drive Q2A Technical Manual 175...

Страница 176: ...5 2 European Standards 176 SIEPYEUOQ2A01G AC Drive Q2A Technical Manual...

Страница 258: ...6 2 Modbus Communications 258 SIEPYEUOQ2A01G AC Drive Q2A Technical Manual...

Страница 356: ...8 7 Storage Guidelines 356 SIEPYEUOQ2A01G AC Drive Q2A Technical Manual...

Страница 357: ...SIEPYEUOQ2A01G AC Drive Q2A Technical Manual 357 9 Disposal 9 1 Safety Precautions 358 9 2 Disposal Instructions 359...

Страница 360: ...9 2 Disposal Instructions 360 SIEPYEUOQ2A01G AC Drive Q2A Technical Manual...

Страница 526: ...11 20 Parameters Changed by PM Motor Code Selection 526 SIEPYEUOQ2A01G AC Drive Q2A Technical Manual...