4.8 Fine Tuning during Test Runs (Adjust the Control Function)

SIEPYEUOQ2A01G AC Drive Q2A Technical Manual

159

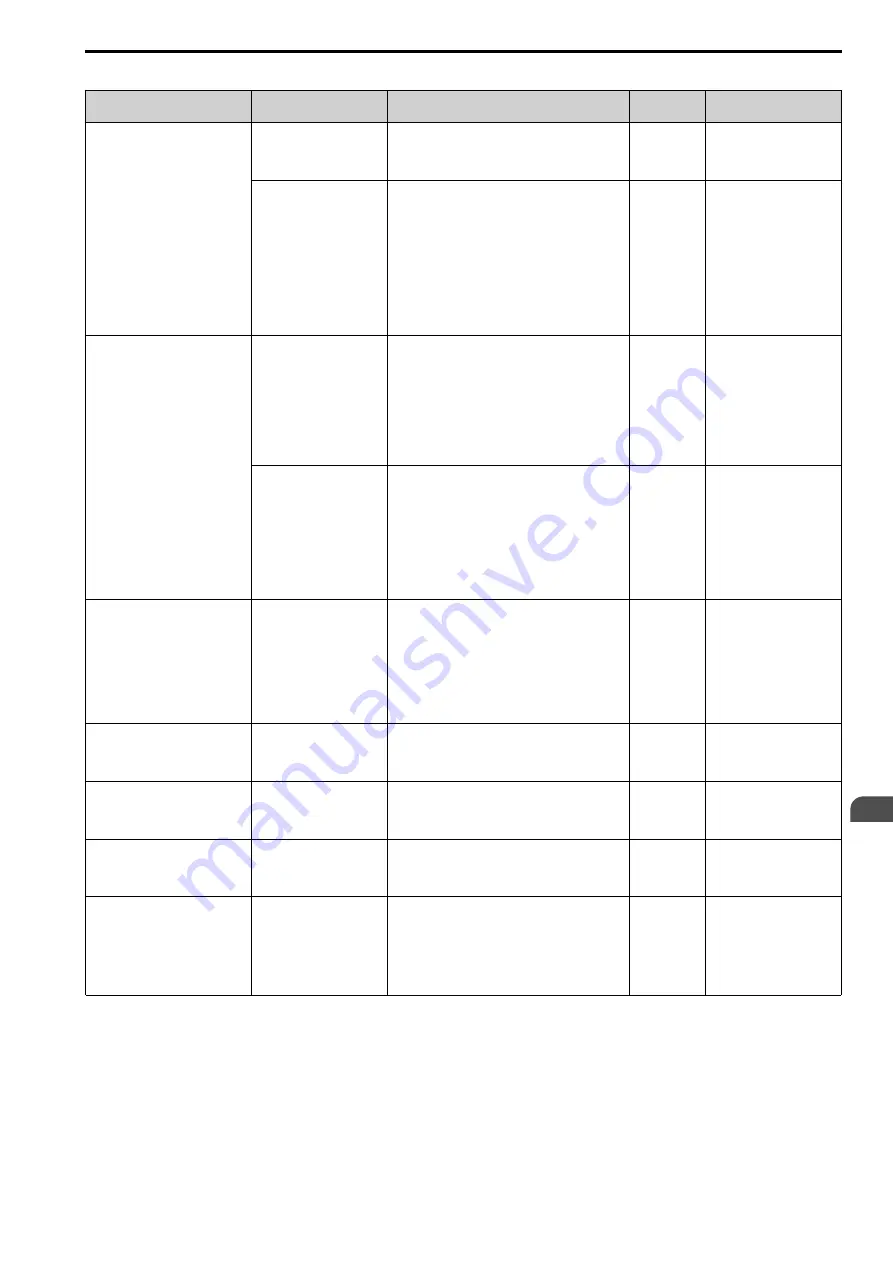

Table 4.18 Parameters for Fine Tuning the Drive (Open Loop Vector Control Method)

Issue

Parameter Number

Solution

Default

Setting

Recommended Setting

•

Torque or speed response are

slow.

•

Hunting or oscillation at mid-

range speeds (10 Hz to 40 Hz)

n2-01 [AFR Gain]

•

To increase the speed of torque or speed response,

decrease the setting value in increments of 0.05.

•

If hunting or oscillation occur, decrease the setting

value in increments of 0.05.

1.00

0.50 - 2.00

n2-02 [AFR Time 1]

•

To increase the speed of torque or speed response,

decrease the setting value in increments of 10 ms

and examine the response.

•

If hunting or oscillation occur or if the load inertia is

too much, increase the setting value in increments of

50 ms and examine the response.

Note:

Make sure that this parameter setting is:

n2-02 ≤

n2-03 [AFR Time 2]

holds true.

When you adjust

n2-02

, you must also increase

the

C4-02 [Trq Comp Delay Time]

value by the

same ratio.

50 ms

50 - 2000 ms

ov [overvoltage]

occurs when the

drive stops accelerating, starts to

decelerate, or when there are large

changes in the load.

n2-03 [AFR Time 2]

•

If

ov

occurs, increase the setting value in increments

of 50 ms and examine the response.

•

If the response is not sufficient, decrease the setting

value in increments of 10 ms and examine the

response.

Note:

Make sure that this parameter setting is:

n2-02

[AFR Time 1] ≤ n2-03

. When you adjust

n2-03

you

must also increase the

C4-06 [M2 Trq Comp Delay

Time]

value by the same ratio.

750 ms

750 - 2000 ms

C4-06 [M2 Trq Comp Delay

Time]

•

If

ov

occurs, increase the setting value in increments

of 10 ms and examine the response.

•

If the response is not sufficient, decrease the setting

value in increments of 2 ms and examine the

response.

Note:

Make sure that this parameter setting is:

C4-02 [Trq

Comp Delay Time] ≤ C4-06

.

When you adjust

C4-06

, you must also increase the

n2-03 [AFR Time 2]

value by the same ratio.

150 ms

150 - 750 ms

•

Torque or speed response are

slow.

•

Hunting or oscillation

C4-02 [Trq Comp Delay

Time]

•

If torque or speed response are slow, decrease the

setting value in increments of 2 ms.

•

If hunting or oscillation occur, increase the setting

value in increments of 10 ms.

Note:

Make sure that this parameter setting is:

C4-02 ≤

C4-06 M2 Trq Comp Delay Time

.

When you adjust

C4-02

, you must also increase the

n2-02 AFR Time 1

value by the same ratio.

20 ms

20 - 100 ms

•

Speed response is slow.

•

Speed is not stable.

C3-02 [Slip Comp Delay

Time]

•

If speed response is slow, decrease the setting value

in increments of 10 ms.

•

If speed is not stable, increase the value in

increments of 10 ms.

200 ms

100 - 500 ms

Speed precision is unsatisfactory.

C3-01 [Slip Comp Gain]

•

If speed is too slow, increase the setting value in

increments of 0.1.

•

If speed is too fast, decrease the setting value in

increments of 0.1.

0.5 - 1.5

•

The volume of the motor

excitation sound is too high.

•

Hunting or oscillation at low

speeds (10 Hz or lower)

C6-02 [Carrier Frequency

Selection]

•

If the volume of the motor excitation sound is too

high, increase the carrier frequency.

•

If hunting or oscillation occur at low speeds,

decrease the carrier frequency.

1 (2 kHz)

0 to upper limit value

•

Torque at low speeds (10 Hz or

lower) is not sufficient. speed

response is slow.

•

Speed response is slow.

•

Large initial vibration at start up.

•

E1-08 [Mid A Voltage]

•

E1-10 [Min Output

Voltage]

•

If torque or speed response are slow, increase the

setting value.

•

If there is large initial vibration at start up, decrease

the setting value

Note:

If the setting value is set too high, a large torque

reference may be output even with light loads.

•

E1-08: 11.0

•

E1-10: 2.0

Default s/- 2 V

*1

Default value changes when

A1-02 [Control Method]

and

o2-04 [Drive KVA Selection]

values change.

*2

Default value changes when

A1-02 [Control Method]

and

E1-03 [V/f Pattern Selection]

values change.

*3

Default value changes when

Drive KVA Selection

and

ND/HD Duty Selection

values change.

*4

Recommended settings are for 200 V class drives. Multiply the voltage by 2 for 400 V class drives.

Содержание Q2A

Страница 2: ...This Page Intentionally Blank 2 SIEPYEUOQ2A01G AC Drive Q2A Technical Manual...

Страница 12: ...12 SIEPYEUOQ2A01G AC Drive Q2A Technical Manual...

Страница 18: ...i 2 Legal Information 18 SIEPYEUOQ2A01G AC Drive Q2A Technical Manual...

Страница 28: ...1 2 Features and Advantages of Control Methods 28 SIEPYEUOQ2A01G AC Drive Q2A Technical Manual...

Страница 64: ...2 9 Installation Methods 64 SIEPYEUOQ2A01G AC Drive Q2A Technical Manual...

Страница 166: ...4 9 Test Run Checklist 166 SIEPYEUOQ2A01G AC Drive Q2A Technical Manual...

Страница 172: ...5 2 European Standards 172 SIEPYEUOQ2A01G AC Drive Q2A Technical Manual...

Страница 173: ...Standards Compliance 5 5 2 European Standards SIEPYEUOQ2A01G AC Drive Q2A Technical Manual 173...

Страница 174: ...5 2 European Standards 174 SIEPYEUOQ2A01G AC Drive Q2A Technical Manual...

Страница 175: ...Standards Compliance 5 5 2 European Standards SIEPYEUOQ2A01G AC Drive Q2A Technical Manual 175...

Страница 176: ...5 2 European Standards 176 SIEPYEUOQ2A01G AC Drive Q2A Technical Manual...

Страница 258: ...6 2 Modbus Communications 258 SIEPYEUOQ2A01G AC Drive Q2A Technical Manual...

Страница 356: ...8 7 Storage Guidelines 356 SIEPYEUOQ2A01G AC Drive Q2A Technical Manual...

Страница 357: ...SIEPYEUOQ2A01G AC Drive Q2A Technical Manual 357 9 Disposal 9 1 Safety Precautions 358 9 2 Disposal Instructions 359...

Страница 360: ...9 2 Disposal Instructions 360 SIEPYEUOQ2A01G AC Drive Q2A Technical Manual...

Страница 526: ...11 20 Parameters Changed by PM Motor Code Selection 526 SIEPYEUOQ2A01G AC Drive Q2A Technical Manual...