6. NORMAL GAIN ADJUSTMENT

6 - 23

(c) Parameter adjustment

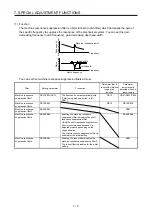

1) [Pr. PB09 Speed loop gain]

This parameter determines the response level of the speed control loop. Increasing this value

enhances response but a too high value will make the mechanical system liable to vibrate. The

actual response frequency of the speed loop is as indicated in the following expression.

Speed loop response frequency [Hz] =

Speed loop gain

2) [Pr. PB10 Speed integral compensation]

To eliminate stationary deviation against a command, the speed control loop is under proportional

integral control. For the speed integral compensation, set the time constant of this integral

control. Increasing the setting lowers the response level. However, if the load to motor inertia

ratio is large or the mechanical system has any vibratory element, the mechanical system is liable

to vibrate unless the setting is increased to some degree. The guideline is as indicated in the

following expression.

Speed integral compensation setting [ms]

≥

2000 to 3000

Speed loop gain/(1 + Load to motor inertia ratio)

3) [Pr. PB07 Model loop gain]

This parameter determines the response level to a speed command. Increasing the value

improves trackability to a speed command, but a too high value will make overshoot liable to

occur at settling.

Model loop gain guideline

≤

(1 + Load to motor inertia ratio)

Speed loop gain

×

8

1

4

1 to

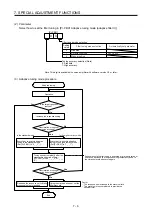

(2) For position control

(a) Parameter

The following parameters are used for gain adjustment.

Parameter Symbol

Name

PB06

GD2

Load to motor inertia ratio/load to motor mass ratio

PB07

PG1

Model loop gain

PB08

PG2

Position loop gain

PB09

VG2

Speed loop gain

PB10

VIC

Speed integral compensation

Содержание MR-J4W2-0303B6

Страница 17: ...8 App 16 Status of general purpose AC servo products for compliance with the China RoHS directive App 58 ...

Страница 39: ...2 INSTALLATION 2 8 MEMO ...

Страница 97: ...4 STARTUP 4 20 MEMO ...

Страница 181: ...6 NORMAL GAIN ADJUSTMENT 6 28 MEMO ...

Страница 235: ...9 DIMENSIONS 9 6 MEMO ...

Страница 245: ...10 CHARACTERISTICS 10 10 MEMO ...

Страница 309: ...13 USING STO FUNCTION 13 14 MEMO ...

Страница 365: ...15 USING A DIRECT DRIVE MOTOR 15 24 MEMO ...

Страница 389: ...16 FULLY CLOSED LOOP SYSTEM 16 24 MEMO ...

Страница 461: ...17 APPLICATION OF FUNCTIONS 17 72 MEMO ...

Страница 556: ...APPENDIX App 41 ...

Страница 585: ...MEMO ...