2. INSTALLATION

2 - 5

(5) Tension

If tension is added on optical cable, the increase of transmission loss occurs because of external force

which concentrates on the fixing part of optical fiber or the connecting part of optical connector. Doing so

may cause the breakage of the optical fiber or damage of the optical connector. For cable laying, handle

without putting forced tension. For the tension strength, refer to section 11.1.2.

(6) Lateral pressure

If lateral pressure is added on optical cable, the optical cable itself distorts, internal optical fiber gets

stressed, and then transmission loss will increase. Doing so may cause the breakage of the optical

cable. As the same condition also occurs at cable laying, do not tighten up optical cable with a thing

such as nylon band (TY-RAP).

Do not trample it down or tuck it down with the door of cabinet or others.

(7) Twisting

If optical fiber is twisted, it will become the same stress added condition as when local lateral pressure or

bend is added. Consequently, transmission loss increases, and the breakage of optical fiber may occur.

(8) Disposal

When incinerating optical cable (cord) used for SSCNET III, hydrogen fluoride gas or hydrogen chloride

gas which is corrosive and harmful may be generated. For disposal of optical fiber, request for

specialized industrial waste disposal services who has incineration facility for disposing hydrogen

fluoride gas or hydrogen chloride gas.

2.5 Inspection items

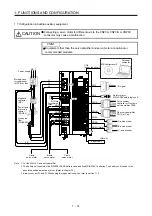

WARNING

Before starting maintenance and/or inspection, turn off the power and wait for 15

minutes or more until the charge lamp turns off. Then, confirm that the voltage

between P+ and N- is safe with a voltage tester or others. Otherwise, an electric

shock may occur. In addition, when confirming whether the charge lamp is off or

not, always confirm it from the front of the servo amplifier.

To avoid an electric shock, only qualified personnel should attempt inspections.

For repair and parts replacement, contact your sales representative.

CAUTION

Do not perform insulation resistance test on the servo amplifier. Otherwise, it may

cause a malfunction.

Do not disassemble and/or repair the equipment on customer side.

It is recommended to make the following checks periodically.

(1) Check for loose terminal block screws. Retighten any loose screws.

(2) Check the cables and wires for scratches and cracks. Inspect them periodically according to operating

conditions especially when the servo motor is movable.

Содержание MR-J4W2-0303B6

Страница 17: ...8 App 16 Status of general purpose AC servo products for compliance with the China RoHS directive App 58 ...

Страница 39: ...2 INSTALLATION 2 8 MEMO ...

Страница 97: ...4 STARTUP 4 20 MEMO ...

Страница 181: ...6 NORMAL GAIN ADJUSTMENT 6 28 MEMO ...

Страница 235: ...9 DIMENSIONS 9 6 MEMO ...

Страница 245: ...10 CHARACTERISTICS 10 10 MEMO ...

Страница 309: ...13 USING STO FUNCTION 13 14 MEMO ...

Страница 365: ...15 USING A DIRECT DRIVE MOTOR 15 24 MEMO ...

Страница 389: ...16 FULLY CLOSED LOOP SYSTEM 16 24 MEMO ...

Страница 461: ...17 APPLICATION OF FUNCTIONS 17 72 MEMO ...

Страница 556: ...APPENDIX App 41 ...

Страница 585: ...MEMO ...