SmartPAC 2 with WPC Integration

1126800

SmartPAC 2 Program Mode

Chapter 5

page 297

To set stop type for red, yellow, green, green quick check, and green constant, select the

setting you want for the sensor—emergency stop, top stop, or Smart Stop.

After you make the stop type settings for red and yellow sensors, you are done. Green

sensors, however, need additional settings to be made. SmartPAC 2 brings you back to the

display listing the remaining sensors. You can set another sensor. Go to the section, "Setting

the other sensors for the tool.”

When you highlight "Smart Stop" and press ENTER, a display immediately appears which

asks you to set "critical angle.”

Critical angle

is the last angle position in the crankshaft

rotation to signal an emergency stop so that the ram can be stopped before the punches make

contact with the material. The critical angle affects all the sensors that are set for Smart Stop,

and only needs to be set

once

for the tool.

If you need to modify the critical angle at a later time, you can access the "Set the critical

Angle" display by pressing

F5

from the "Setting stop type" display (Figure 5-16).

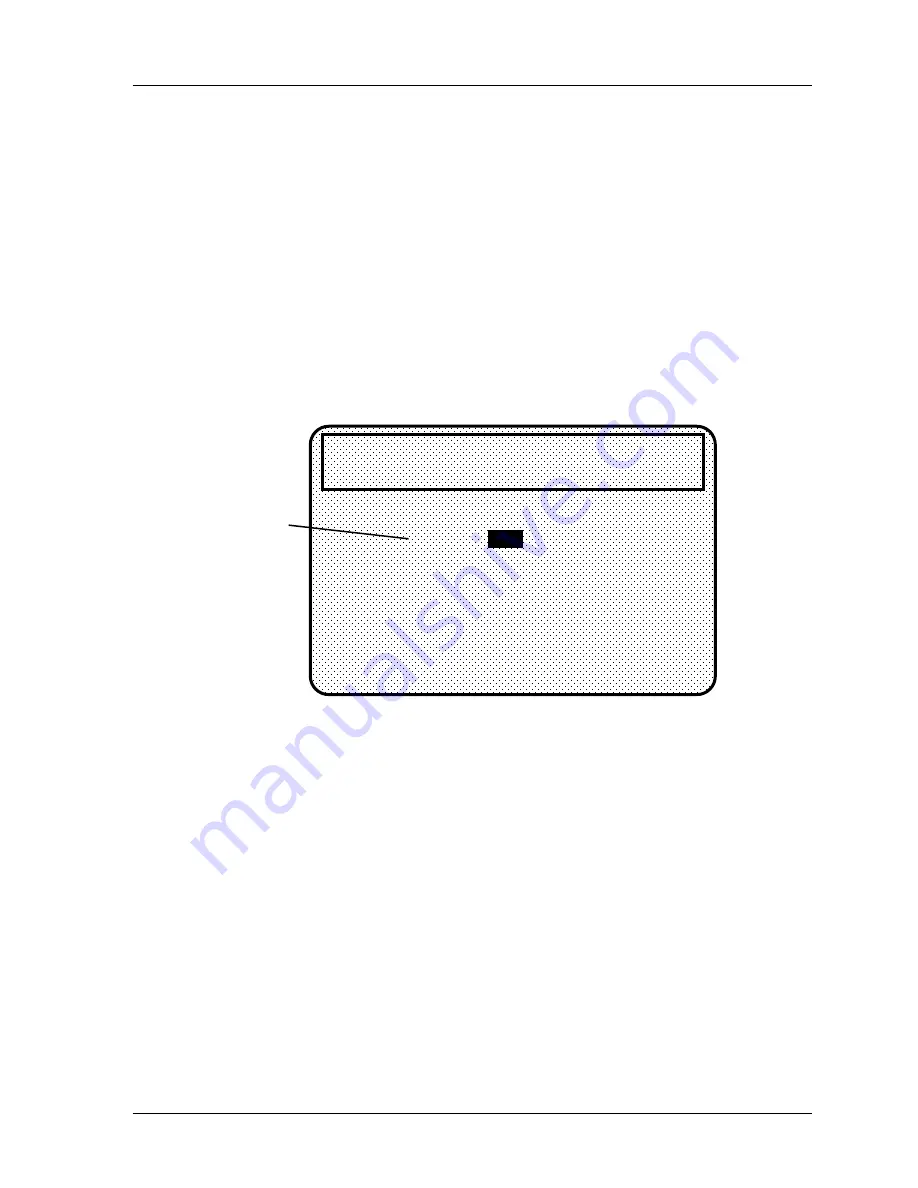

critical

angle

setting

for all

sensors

in the

tool set

for

variable

stop

CRITICAL ANGLE FOR THIS TOOL

DEGREES

THIS AFFECTS ALL SENSORS SET FOR

VARIABLE STOP FOR THIS TOOL. USE THE

CURSOR KEYS TO CHANGE THE ANGLE. PRESS

THE ENTER KEY WHEN DONE. PRESS THE

RESET KEY TO CANCEL.

IS

TOOL NUMBER 1234567

CHAIR BRACKET

CRITICAL ANGLE 59

59

SENSOR 2

TRANSFER

GREEN SMART

Figure 5 - 23. Setting critical angle for variable-stop sensors

Use cursor keys to change the angle value. Then press ENTER when done (see Chapter 3 for

help in using cursor keys). You will be able to continue setting up the sensor.

Next we explain how to set the ready signal for green, green quick check, and green constant

sensors and the counter for green special sensors.

Setting the Ready Signal for a Green Sensor

After selecting stop type for a green sensor, you will see the display in which you set the

ready signal the "ready on" angle and "ready off" angle (the "ready signal"). The ready signal

is the timing window during which the sensor must actuate or SmartPAC 2 sends the stop

signal to the press.

You .set the ready signal; so that it is a little longer than the sensor's actuation time for green

and green quick check sensors. For green constant sensors, you set it so that it is a little

shorter than the sensor's actuation time. See Chapter 1 for an explanation of the different

types of green sensors.

Содержание SmartPAC 2

Страница 192: ...1126800 SmartPAC 2 with WPC Integration Page 170 Chapter 2 Installing SmartPAC 2 and WPC ...

Страница 222: ...1126800 SmartPAC 2 with WPC Integration Page 200 Chapter 3 SmartPAC 2 Keyboard Displays and Operating Modes ...

Страница 294: ...1126800 SmartPAC 2 with WPC Integration Page 272 Chapter 4 SmartPAC 2 Initialization Mode ...

Страница 342: ...1126800 SmartPAC 2 with WPC Integration page 320 Chapter 5 SmartPAC 2 Program Mode ...

Страница 404: ...1126800 SmartPAC 2 with WPC Integration Page 382 Chapter 6 SmartPAC 2 Run Mode ...

Страница 448: ...1126800 SmartPAC 2 with WPC Integration Page 426 Chapter 7 SmartPAC 2 Fault Messages ...

Страница 476: ...1126800 SmartPAC 2 with WPC Integration page 454 Appendix C Updating SmartPAC 2 Firmware ...

Страница 478: ...1126800 SmartPAC 2 with WPC Integration page 456 Appendix D SmartView Remote Viewing and E mail Setup ...

Страница 480: ...1126800 SmartPAC 2 with WPC Integration page 458 Appendix E Upgrade from Original SmartPAC to SmartPAC 2 ...

Страница 482: ...1126800 SmartPAC 2 with WPC Integration page 460 Appendix F Replacing SmartPAC 2 PC Board ...

Страница 492: ...1126800 SmartPAC 2 with WPC Integration page 470 Glossary ...