Chapter 14

14-23

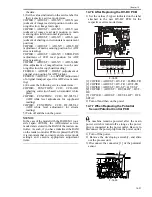

2. Making Use of Non-Auto Control Mode

If a fault occurs in images, use the mode to find

out if the cause is on the input side or output side

of the microprocessor on the DC controller PCB.

In non-auto control mode, if the fault is corrected

somewhat, you may suspect the potential meas-

urement unit or the DC controller PCB.

c. Zero-Level Check

One way of finding out if the surface potential

control circuit is good or not is to use a zero-level

check.

MEMO:

A zero-level check is made to see if the micro-

processor registers 0 V when the surface potential

of the drum is 0 V.

Using the result of the check, you can find out if

the microprocessor on the DC controller PCB or

the measurement unit is good or not; a zero-level

check may take either of the following two meth-

ods:

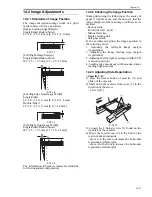

1. Method 1

1) Turn off the power switch.

2) Short the connectors J522-1 and -2 on the DC

controller PCB with a jumper wire, and

disconnect the connector J3 of the potential

control PCB.

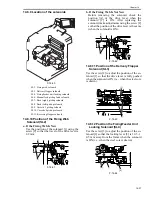

F-14-44

3) Fit the door switch actuator into the door

switch assembly, and turn on the power switch.

4) Make the following selections in service mode,

and check to see if the reading is between 0 and

30 during initial rotation: COPIER>

DISPLAY> DPOT> DPOT-K.

MEMO:

If the reading is not as indicated, you may suspect

a fault in the DC controller PCB.

5) Turn off the power switch, and detach the door

switch actuator.

6) Detach the jumper wire from the DC controller

PCB.

7) Connect the connector to J3 of the potential

control PCB.

8) Turn on the power switch.

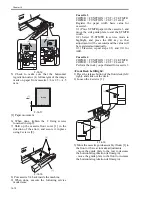

2. Method 2

1) Turn off the power switch.

2) Remove the developing assembly, and slide

out the process unit.

3) Disconnect the connector [1] of the potential

sensor.

F-14-45

4) Remove the 2 screws [1], and detach the

potential sensor support plate [2].

F-14-46

5) Put back the developing assembly and the

process unit.

6) Connect the connector [1] of the potential

sensor.

F-14-47

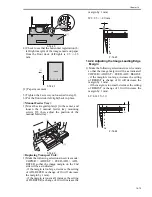

7) Fit the potential sensor checker electrode

(FY9-3041) [2] to the potential sensor [1].

When fitting the checker electrode to the poten-

tial sensor, be sure that the magnet of the checker

electrode will not come into contact with the po-

tential sensor cover.

Connector

J3

J522

[1]

[2]

[1]

[1]

Содержание IMAGERUNNER 7095 PRINTER

Страница 20: ...Chapter 1 Introduction...

Страница 46: ...Chapter 2 Installation...

Страница 88: ...Chapter 3 Basic Operation...

Страница 94: ...Chapter 4 Main Controller...

Страница 116: ...Chapter 5 Original Exposure System...

Страница 165: ...Laser Exposure Chapter 6...

Страница 175: ...Chapter 7 Image Formation...

Страница 180: ...Chapter 7 7 3 7 3 Basic Sequence 7 3 1 Basic Sequence 0010 8038 F 7 3 ON ON WMUPR WMUP STBY OFF 100msec...

Страница 231: ...Chapter 8 Pickup Feeding System...

Страница 287: ...Chapter 9 Fixing System...

Страница 312: ...Chapter 10 External and Controls...

Страница 346: ...Chapter 11 MEAP...

Страница 350: ...Chapter 12 RDS...

Страница 360: ...Chapter 13 Maintenance Inspection...

Страница 375: ...Chapter 14 Standards Adjustments...

Страница 407: ...Chapter 15 Correcting Faulty Images...

Страница 433: ...Chapter 16 Self Diagnosis...

Страница 460: ...Chapter 17 Service Mode...

Страница 559: ...Chapter 18 Upgrading...

Страница 583: ...Chapter 19 Service Tools...

Страница 584: ...Contents Contents 19 1 Service Tools 19 1 19 1 1 Special Tools Table 19 1 19 1 2 Solvents Oils 19 2...

Страница 588: ...APPENDIX...

Страница 615: ......