Chapter 7

7-6

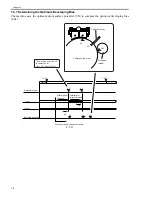

7.4.3 Determining the Optimum Grid Bias

0010-8041

The grid bias is determined so that the drum surface potential will be identical to the target potential. (The

primary charging bias is set to a fixed value.)

F-7-7

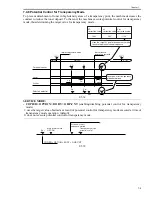

7.4.4 Grid Bias Corrective Control

0010-8042

If the optimum grid bias cannot be determined at the end of drum surface potential measurement, the ma-

chine starts its compensatory control sequence to determine the bias.

F-7-8

WMUPR

WMUP

STBY

193

198

Potential sensor

Primary charging bias

Grid bias

650 V

550 V or 750 V

Measurement(VD2) Measurement(VD1orVD3) Measurement (target VD)

Vg

550V 650V 750V

VD1

VD2

VD3

Grid bias

Measurements are taken multiple times to

determine the relationship between the drum

surface potential (VD) and the grid bias.

A grid bias (Vg) needed to attain

the target VD is determined.

Potential control sequence started

Charging characteristics

curve

If the target VD is attained using this

measurement, the control is ended;

otherwise, compensatory control is

After measuring VD2, VD1 will be measured

if VD2 is greater than the target VD; if smaller,

VD3 will be measured.

WMUPR

WMUP

STBY

193

198

Potential sensor

Primary charging bias(DC)

Grid bas

650 V

550 V

or

750 V

Vg

Vg1 Vg2 Vg3

Vg8

VD1

VD-NG

VD2

VD3

Continues to take measurements while varying

the value of the grid bias so that it will be closer

to the target VD.

Potential control

sequence started

Compensatory control

sequence started

VD-NG VD1 VD2

VD3

VD8

TargetVD

A grid bias (Vg) needed to attain the

target VD is determined.

When the measurement is identical to the target VD,

ends the control. The machine executes measurement a

maximum of 8 times, possibly using an approximate

target VD.

Содержание IMAGERUNNER 7095 PRINTER

Страница 20: ...Chapter 1 Introduction...

Страница 46: ...Chapter 2 Installation...

Страница 88: ...Chapter 3 Basic Operation...

Страница 94: ...Chapter 4 Main Controller...

Страница 116: ...Chapter 5 Original Exposure System...

Страница 165: ...Laser Exposure Chapter 6...

Страница 175: ...Chapter 7 Image Formation...

Страница 180: ...Chapter 7 7 3 7 3 Basic Sequence 7 3 1 Basic Sequence 0010 8038 F 7 3 ON ON WMUPR WMUP STBY OFF 100msec...

Страница 231: ...Chapter 8 Pickup Feeding System...

Страница 287: ...Chapter 9 Fixing System...

Страница 312: ...Chapter 10 External and Controls...

Страница 346: ...Chapter 11 MEAP...

Страница 350: ...Chapter 12 RDS...

Страница 360: ...Chapter 13 Maintenance Inspection...

Страница 375: ...Chapter 14 Standards Adjustments...

Страница 407: ...Chapter 15 Correcting Faulty Images...

Страница 433: ...Chapter 16 Self Diagnosis...

Страница 460: ...Chapter 17 Service Mode...

Страница 559: ...Chapter 18 Upgrading...

Страница 583: ...Chapter 19 Service Tools...

Страница 584: ...Contents Contents 19 1 Service Tools 19 1 19 1 1 Special Tools Table 19 1 19 1 2 Solvents Oils 19 2...

Страница 588: ...APPENDIX...

Страница 615: ......