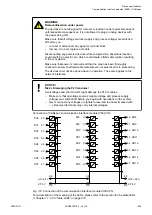

Range

Pt100 / Pt1000

-50...400 °C

Ni1000

-50...150 °C

Digital value

Decimal

Hex.

160.0 °C

:

150.1 °C

1600

:

1501

0640

:

05DD

800

:

701

0320

:

02BD

Normal range

400.0 °C

:

:

:

0.1 °C

150.0 °C

:

:

0.1 °C

4000

1500

700

:

1

0FA0

05DC

02BC

:

0001

0.0 °C

0.0 °C

0

0000

-0.1 °C

:

-50.0 °C

-0.1 °C

:

-50,0 °C

-1

:

-500

FFFF

:

FE0C

Measured value

too low

-50.1 °C

:

-60.0 °C

-50.1 °C

:

-60.0 °C

-501

:

-600

FE0B

:

FDA8

Underflow

< -60.0 °C

< -60.0 °C

-32768

8000

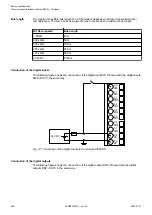

Output ranges voltage and current

Range

-10...+10 V

0...20 mA

4...20 mA

Digital value

Decimal

Hex.

Overflow

0 V

0 mA

0 mA

> 32511

> 7EFF

Measured

value too high

11.7589 V

:

10.0004 V

23.5178 mA

:

20.0007 mA

22.8142 mA

:

20.0006 mA

32511

:

27649

7EFF

:

6C01

Normal range 10.0000 V

:

0.0004 V

20.0000 mA

:

0,0007 mA

20.0000 mA

:

4.0006 mA

27648

:

1

6C00

:

0001

0.0000 V

0.0000 mA

4.0000 mA

0

0000

-0.0004 V

:

-10.0000 V

0 mA

:

0 mA

3.9994 mA

0 mA

0 mA

-1

-6912

-27648

FFFF

E500

9400

Device specifications

Communication interface modules (S500) > CANopen

2022/01/31

3ADR010278, 3, en_US

651