Po

sit

io

n

in

g

Chapter 9 Positioning Error Information & Solutions

9-

15

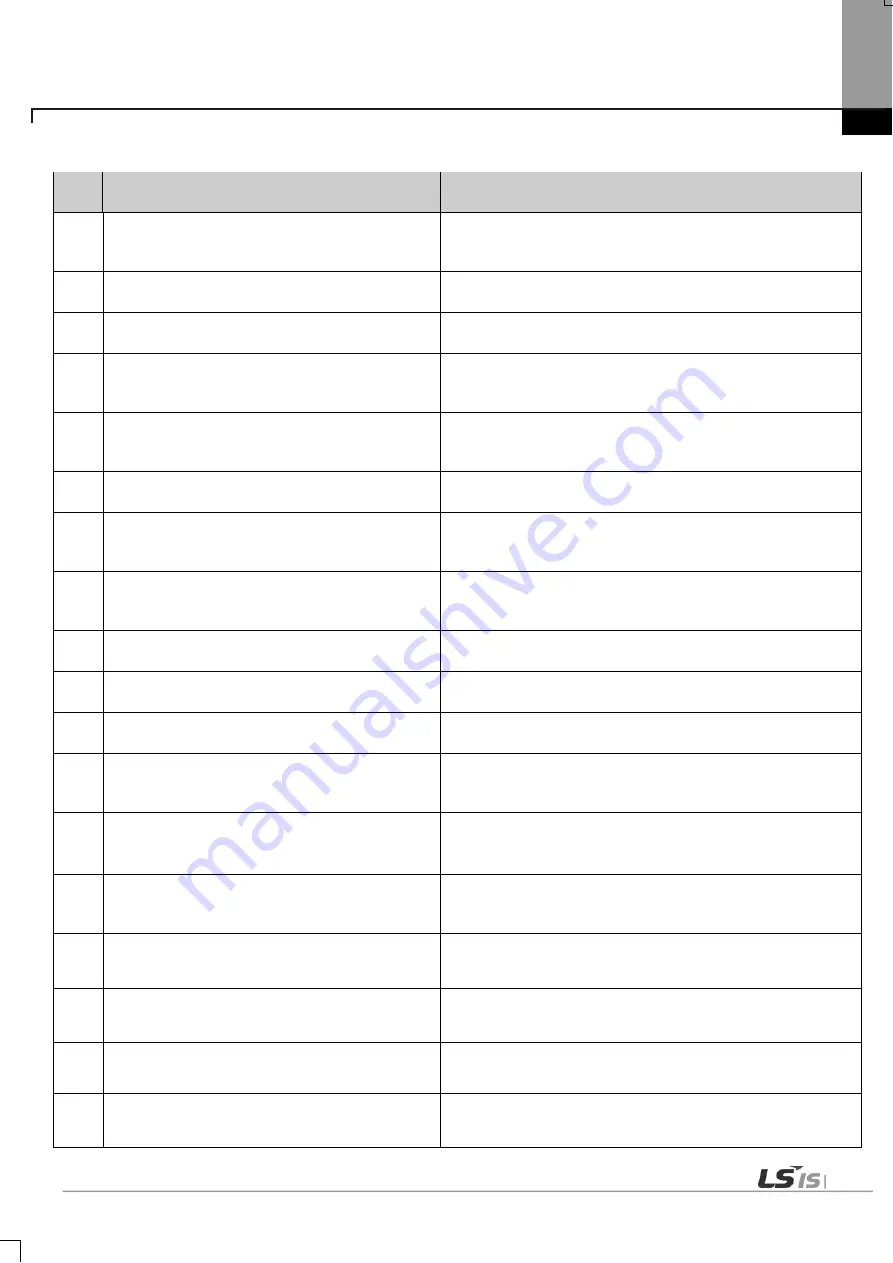

Error

Code

Error Description

Solutions

554

Radius setting error from Ellipse interpolation.

The range of possible execution for Ellipse Interpolation is between

0 and 2147483647. Set radius of circle from its range, smaller than

2147483647pulse.

555

Exact circle cannot be draw because of degree

of Ellipse interpolation is bigger than 90

°

Set lower for operation speed so that degree

of Ellipse interpolation is smaller than 90

°

556

Continuous operation cannot be done for

Ellipse interpolation.

Execute Ellipse interpolation after terminate

operation step of circular interpolation.

557

Ellipse interpolation only can be operated

when control setting is circular interpolation.

Execute Ellipse interpolation after change

control setting for drive step of Ellipse

interpolation to circular interpolation.

558

Operation cannot be executed when beginning

point and end point of ellipse interpolation are

not same.

Execute Ellipse interpolation after set the goal

Position of ellipse interpolation operating step

Same as current position.

559

Operation cannot be executed when operating

degree of ellipse interpolation is “0.”

Set the value of operating degree for ellipse

interpolation, larger than “0.”(1~65535)

571

Operation cannot be executed because of error from

sub-coordinate axis of main axis by current axis.

Check the error from subordinate axis of main

axis by current axis whether it is occurred

during the operation of current axis.

572

Operation cannot be executed because of error

from sub coordinate axis of main axis by

interpolated axis.

Check the error from subordinate axis of main

axis by current axis whether it is occurred

during the operation of interpolated axis.

701

Not possible to carry out CAM command in the

state of in operation.

Execute CAM command when main axis is not

operating.

702

Not possible to carry out CAM command in the

state of M Code ON

Execute CAM command after set M Code OFF

from commanding axis with XMOF.

703

Not possible to carry out CAM command in the

state that Drive Ready is OFF.

Execute CAM command when Drive Ready is

“ON.”

704

Error of setting main/subordinate axis from

CAM command.

Set main axis for CAM command as other axis

besides its command axis from connecting axis.

Set parameters are 1axis through 4axis.

705

CAM command of main axis cannot be

executed during the operation.

Execute CAM command when the main axis

setting of CAM command is not operating.

706

Error of CAM block setting from CAM

command.

Execute CAM command after set a CAM block

from CAM command as bigger than 1 and

smaller than 8.

707

Error for CAM data of appointed block from

CAM command.

Execute CAM command after set right data for

appointed block from CAM command.

708

The speed of subordinate axis from CAM

command cannot exceed its speed limit.

Set lower speed for main axis so that speed of subordinate axis

from CAM data which is calculated by subordinate position would

not exceed its speed limit.

709

For CAM command, in case main axis is encoder,

main axis unit if CAM data should be pulse.

When you set the main axis of CAM data as encoder, set the unit of

main axis of CAM block as pulse.

710

The speed of the master axis of cam command is so

high that moving position per control period exceeds

the master axis scope.

After slow down the speed of the master axis then operate the axis.

Содержание XBE-DC08A

Страница 124: ...Main Chapter 1 Configuration and Operation Mode of Programs 1 27 1 Memory block diagram ...

Страница 155: ...Main Chapter 2 CPU Function 2 29 Notice For more details on the monitor refer to the XG5000 manual ...

Страница 504: ...Position Chap 6 Commands 6 61 6 11 Function blocks related to Servo Drive ...

Страница 512: ...Positioning Chapter 7 Program 7 8 manual operation 7 1 4 Parameter and Operation Data Setting 1 Parameter Setting ...

Страница 644: ...Positioning Chapter 8 Functions 8 91 ...

Страница 727: ...Positioning Chapter 9 Positioning Error Information Solutions 9 13 ...

Страница 861: ...Special Chapter 1 Embedded Analog 1 39 5 Select View Variables Comments Variables and comments are both displayed ...

Страница 1206: ...Appendix 2 Dimension App2 1 Appendix 2 Dimension Unit mm 1 CPU Type XEC DN32U 2 Positioning Type XEC DN32UP ...

Страница 1207: ...Appendix 2 Dimension App2 2 2 Analog Type XEC DN32UA ...

Страница 1209: ...Appendix 2 Dimension App2 4 XBE DC08A XBE DC16A XBE TN08A XBE TN16A XBE DR16A XBE RY08A ...

Страница 1210: ...Appendix 2 Dimension App2 5 4 Extension Cnet I F Module XBL C41A XBL C21A ...