Control panels

68

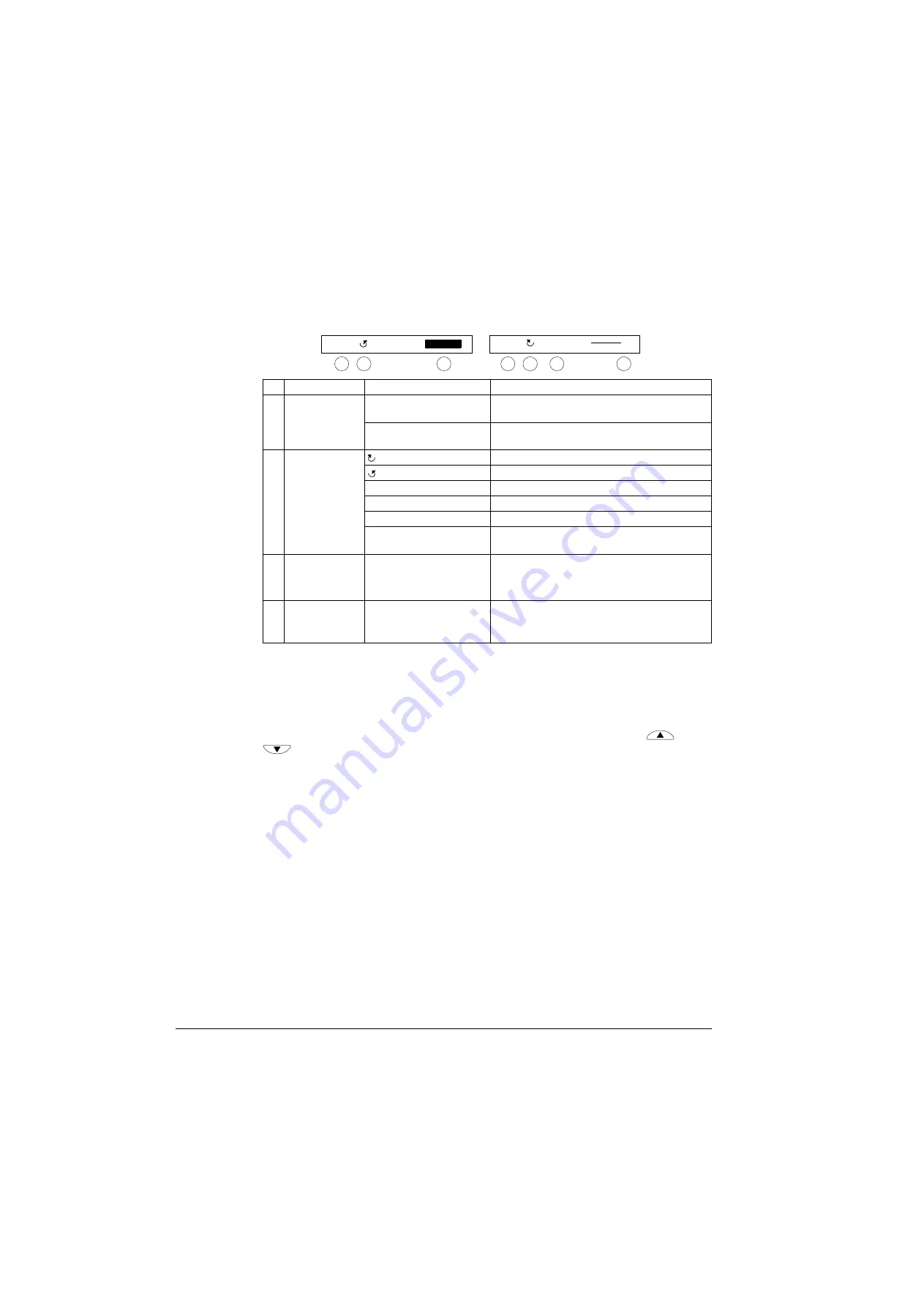

Status line

The top line of the LCD display shows the basic status information of the drive.

Operation

You operate the control panel with menus and keys. The keys include two context-

sensitive soft keys, whose current function is indicated by the text shown in the

display above each key.

You select an option, e.g. operation mode or parameter, by scrolling the

and

arrow keys

until the option is highlighted (in reverse video) and then pressing

the relevant soft key. With the right soft key you usually enter a mode, accept an

option or save the changes. The left soft key is used to cancel the made changes

and return to the previous operation level.

The Assistant Control Panel has nine panel modes: Output, Parameters, Assistants,

Changed Parameters, Fault Logger, Time and Date, Parameter Backup, I/O Settings

and Fault. The operation in the first eight modes is described in this chapter. When a

fault or alarm occurs, the panel goes automatically to the Fault mode showing the

fault or alarm. You can reset it in the Output or Fault mode (see chapter

No. Field

Alternatives

Significance

1 Control location

LOC

Drive control is local, that is, from the control

panel.

REM

Drive control is remote, such as the drive I/O or

fieldbus.

2 State

Forward shaft direction

Reverse shaft direction

Rotating arrow

Drive is running at setpoint.

Dotted rotating arrow

Drive is running but not at setpoint.

Stationary arrow

Drive is stopped.

Dotted stationary arrow

Start command is present, but the motor is not

running, e.g. because start enable is missing.

3 Panel operation

mode

• Name of the current mode

• Name of the list or menu shown

• Name of the operation state, e.g. PAR EDIT.

4 Reference value

or number of the

selected item

• Reference value in the Output mode

• Number of the highlighted item, e.g mode,

parameter group or fault.

49.1Hz

LOC

1

2

4

LOC

MAIN MENU

1

1

2

3

4

Summary of Contents for ACS350 Series

Page 1: ...ACS350 User s Manual ACS350 Drives 0 37 22 kW 0 5 30 HP ...

Page 4: ......

Page 8: ...Safety 8 ...

Page 18: ...Table of contents 18 ...

Page 24: ...Hardware description 24 ...

Page 44: ...Installation checklist 44 ...

Page 56: ...Start up control with I O and ID Run 56 ...

Page 140: ...Program features 140 ...

Page 242: ...Actual signals and parameters 242 ...

Page 266: ...Fieldbus control with embedded fieldbus 266 ...

Page 284: ...Fault tracing 284 ...

Page 288: ...Maintenance and hardware diagnostics 288 ...

Page 309: ...Dimensions 309 Frame size R2 IP20 NEMA 1 3AFE68586658 A Frame size R2 IP20 NEMA 1 VAR EMC ...

Page 311: ...Dimensions 311 Frame size R3 IP20 NEMA 1 3AFE68579872 B Frame size R3 IP20 NEMA 1 VAR EMC ...

Page 313: ......