13

– 5

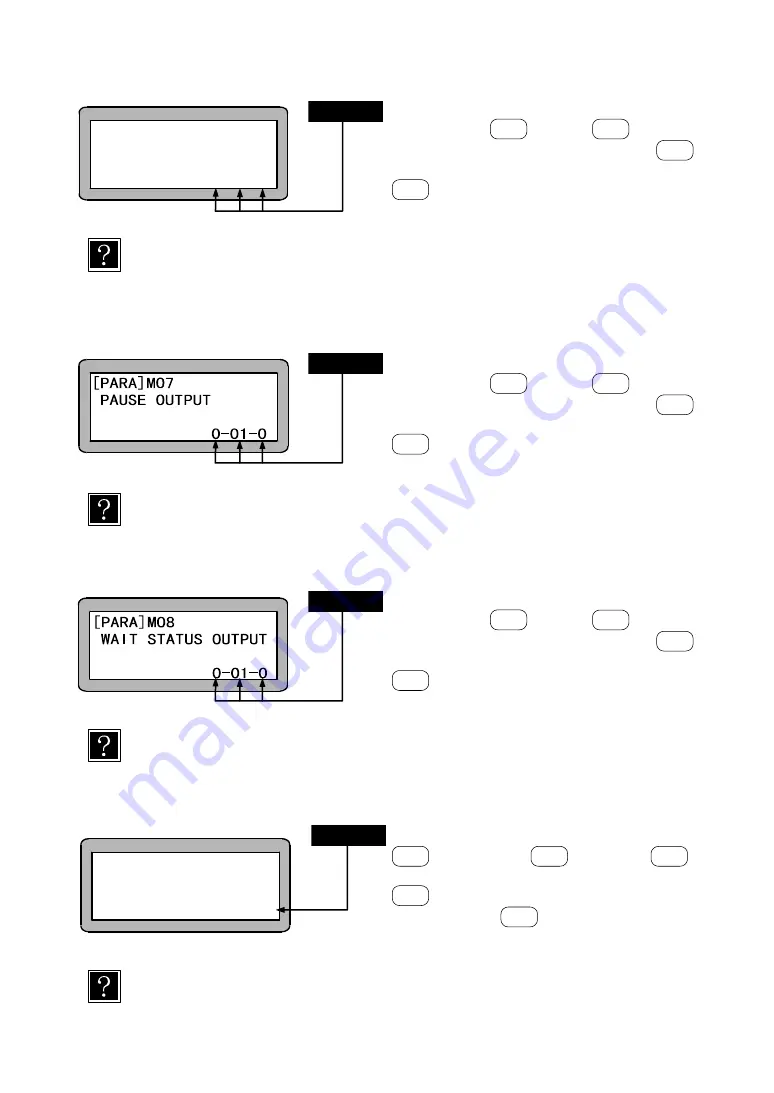

13.2.6 Designation of return to origin input bit

Use the numeric keypad to designate the input

bit and press

ENT

. When

NEXT

is pressed,

the next screen will display, and when

-NEXT

is

pressed, the previous screen will display. Press

ESC

to return to the PARA mode screen.

The initial value (port 01-5) of the return to origin input is decided, but it can be

changed with this bit designation.

When CC-link is used, this parameter is not available.

13.2.7 Designation of pausing output bit

Use the numeric keypad to designate the output

bit and press

ENT

. When

NEXT

is pressed,

the next screen will display, and when

-NEXT

is

pressed, the previous screen will display. Press

ESC

to return to the PARA mode screen.

When the pausing output bit is designated, the designated bit will turn ON while

operation is paused (temporarily stopped). (Refer to section 10.2.16.)

13.2.8 Designation of input wait output bit

Use the numeric keypad to designate the output

bit and press

ENT

. When

NEXT

is pressed,

the next screen will display, and when

-NEXT

is

pressed, the previous screen will display. Press

ESC

to return to the PARA mode screen.

When the input wait output bit is designated, the designated bit will remain ON while

the program is waiting for the input of the IN command. (Refer to section 10.2.15.)

13.2.9 Setting of Teach Pendant display (Japanese/English) mode

Switch between Japanese/English by pressing

ALT

and press

ENT

. When

NEXT

is

pressed, the next screen will display, and when

-NEXT

is pressed, the previous screen will

display. Press

ESC

to return to the PARA

mode screen.

J: Japanese E: English

The display here refers to the display of the Teach Pendant screens.

[

P

A

R

A

]

M

0

6

R

E

T

U

R

N T

O O

R

G

.

I

N

P

U

T

0

-

0

1

-

0

STEP 1

STEP 1

STEP 1

[PARA]M09

DISPLAY J:JAPANESE

E:ENGLISH

[J ]

STEP 1

Содержание CA20-M10

Страница 2: ......

Страница 14: ...XII 21 6 Spare parts 21 5 21 6 1 Controller spare parts 21 5 21 6 2 Axis spare parts 21 5...

Страница 24: ...1 10 This page is blank...

Страница 104: ...4 20 This page is blank...

Страница 112: ...5 8 This page is blank...

Страница 152: ...7 20 This page is blank...

Страница 190: ...10 20 This page is blank...

Страница 234: ...11 44 This page is blank...

Страница 244: ...12 10 This page is blank...

Страница 286: ...15 4 This page is blank...

Страница 300: ...17 12 This page is blank...

Страница 352: ...18 52 This page is blank...

Страница 382: ...21 6 This page is blank...

Страница 383: ......

Страница 384: ...Back cover Q3178E 03 APR 20...