E70 Series Instruction Manual

3.3 Tool Measurement

I - 141

Menus

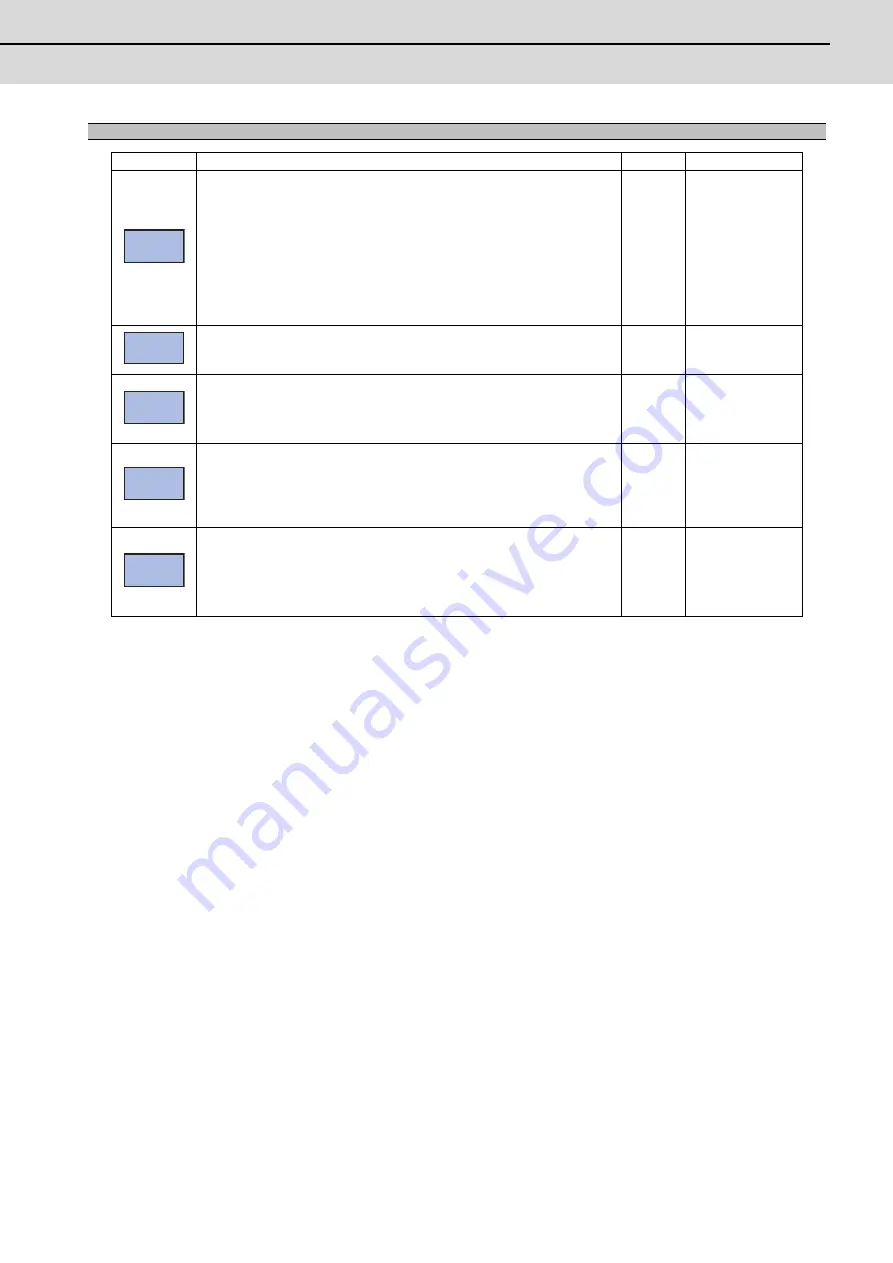

Menu

Details

Type

Reference

This writes the value displayed in "Mea value" as the tool compensation amount.

The wear amount is cleared to "0" for the tool compensation type II.

The tool compensation amount cannot be written in when the menu [Offset No.]

or [Surface hight] is highlighted.

(Note) When the parameter "#8924 MEAS. CONFIRM MSG" is "1", this menu is

highlighted and the operation message "OK? (Y/N)" appears. The measurement

result is written as tool compensation amount by pressing [Y] or [INPUT] key.

Even if other key is pressed, the result is not written.

When this menu is pressed again while displaying the message, the highlight is

released and the operation message is erased.

C

When the offset No. is set and the [INPUT] key is pressed, the tool compensation

data with that number at its head appears.

The cursor moves to the length dimension data of the top line of that data.

A

3.2.1 Setting the Tool

Compensation Data

This sets the reference surface height data. (The cursor moves to the reference

surface height.)

A

When the data is set in the input area and the [INPUT] key is pressed, the

reference surface height is set.

This changes the mode to the tool length measurement mode.

This mode is enabled when turning ON the power.

B

Carrying Out Tool

Length Measurement

(The cursor moves to the length dimension position for tool compensation type

II. Only the length dimensions and length wear are displayed when "#11050 T-

ofs digit type" is set to "1".)

This changes the mode to the tool radius measurement mode.

B

Carrying Out Tool

Radius Measurement

(The tool measurement type is valid only for tool length measurement II.)

(The cursor moves to the radius dimension position for tool compensation type

II. Only the radius dimension and radius wear are displayed when "#11050 T-ofs

digit type" is set to "1".)

Offset

write

Offset

No.

Surface

hight

T-leng

measure

T-rad.

measure

Содержание E70 Series

Страница 1: ......

Страница 3: ......

Страница 9: ......

Страница 11: ......

Страница 13: ......

Страница 15: ......

Страница 24: ...I SCREEN OPERATIONS ...

Страница 25: ......

Страница 26: ...I 1 1 Operating the Setting and Display Unit ...

Страница 57: ...1 Operating the Setting and Display Unit MITSUBISHI CNC I 32 ...

Страница 58: ...I 33 2 Monitor Screens ...

Страница 139: ...2 Monitor Screens MITSUBISHI CNC I 114 ...

Страница 140: ...I 115 3 Setup Screens ...

Страница 232: ...I 207 4 Edit Screens ...

Страница 286: ...E70 Series Instruction Manual 4 4 Program Input Output I 261 During file transmission During file setting 1 2 4 3 5 6 7 ...

Страница 314: ...I 289 5 Diagnosis Screens ...

Страница 355: ...5 Diagnosis Screens MITSUBISHI CNC I 330 ...

Страница 356: ...I 331 6 Maintenance Screens ...

Страница 436: ...II MACHINE OPERATIONS ...

Страница 437: ......

Страница 439: ...MITSUBISHI CNC II 2 ...

Страница 440: ...II 3 1 Operation State ...

Страница 444: ...II 7 2 Indicator Lamps ...

Страница 446: ...II 9 3 Reset Switch and Emergency Stop Button ...

Страница 448: ...II 11 4 Operation Mode ...

Страница 456: ...II 19 5 Operation Panel Switches in Operation Mode ...

Страница 460: ...II 23 6 Operation Panel Switch Functions ...

Страница 495: ...6 Operation Panel Switch Functions MITSUBISHI CNC II 58 ...

Страница 496: ...II 59 7 Other Functions ...

Страница 509: ...7 Other Functions MITSUBISHI CNC II 72 ...

Страница 510: ...III MAINTENANCE ...

Страница 511: ......

Страница 512: ...III 1 1 Daily Maintenance and Periodic Inspection and Maintenance ...

Страница 515: ...1 Daily Maintenance and Periodic Inspection and Maintenance MITSUBISHI CNC III 4 ...

Страница 516: ...III 5 2 Hardware Replacement Methods ...

Страница 531: ...2 Hardware Replacement Methods MITSUBISHI CNC III 20 ...

Страница 532: ...IV APPENDIXES ...

Страница 533: ......

Страница 534: ...IV 1 Appendix 1 List of Function Codes ...

Страница 536: ...IV 3 Appendix 2 Table of Command Value Ranges ...

Страница 543: ...Appendix 2 Table of Command Value Ranges MITSUBISHI CNC IV 10 ...

Страница 544: ...IV 11 Appendix 3 Circular Cutting Radius Error ...

Страница 546: ...IV 13 Appendix 4 Registering Editing the Fixed Cycle Program ...

Страница 561: ...Appendix 4 Registering Editing the Fixed Cycle Program MITSUBISHI CNC IV 28 ...

Страница 562: ...IV 29 Appendix 5 RS 232C I O Device Parameter Setting Examples ...

Страница 564: ...IV 31 Appendix 6 Explanation of Alarms ...

Страница 678: ...IV 145 Appendix 7 Operation Messages ...

Страница 699: ...Appendix 7 Operation Messages MITSUBISHI CNC IV 166 ...

Страница 700: ...IV 167 Appendix 8 User Parameters ...

Страница 777: ...Appendix 8 User Parameters MITSUBISHI CNC IV 244 ...

Страница 782: ......