User Manual Of EL7-EC** AC Servo

215

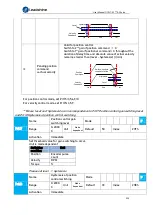

If auto gain adjustment is valid, the parameters listed above can’t be manually modified.

Only when Pr0.02 = 0x00 or 0x10, can the gain related parameters be modified manually.

Gain related parameters that don’t change with the real time gain adjustment

No.

Parameter Label

1

Pr1.10

Velocity feedforward gain constant

2

Pr1.11

Velocity feedforward filter time constant

3

Pr1.12

Torque feedforward gain

4

Pr1.13

Torque feedforward filter time constant

5

Pr1.15

Position control gain switching mode

6

Pr1.17

Position control switching level

7

Pr1.18

Position control switching hysteresis

18

Pr1.19

Position gain switching time

Pr0.02

Name

Real time Auto Gain

Adjusting

Valid

Mode

F

Range

0x0~0xFF

F

Unit

—

Default

0x001

Index

2002h

Activation

Immediate

Set up the mode of the real time auto gain adjusting.

Data

bits

Category

Settings

Application

0x00_

Motion

setting

mode

Used to set motion setting mode, which can be selected according to the

motion characteristics or setting requirements. Generally, it is

recommended to select mode 1 with good generality when there is no

special requirement, mode 2 when rapid positioning is needed If mode 1

and mode 2 cannot meet the requirements, please choose mode 0.

0:Manual

Pr0.03 invalid. Gain value must be adjusted manually

and accordingly.

1:Standard

Pr0.03 valid. Quick gain adjusting can be achieved by

changing Pr0.03 stiffness value. Gain switching is not

used in this mode, suitable for applications with

requirements for stability.

2:Positioning

Pr0.03 valid. Quick gain adjusting can be achieved by

changing Pr0.03 stiffness value. This mode is suitable

for applications requiring quick positioning. Not

recommended for load mounted vertical to ground, or

please compensate for the load using Pr6.07

0x0_0 Load type

setting

Used to select the load type, choose according to load-inertia ratio and

mechanical structure.

0: Rigid

structure

This mode prioritizes system responsiveness. Use this

mode when there is a relatively rigid structure with low

load inertia. Typical application including directly

connected high-precision gearbox, lead screw, gears,

etc.

1:High inertia

For applications with higher load inertia (10 times or

above), gain settings take into account both machine

stability and responsiveness. Not recommended to set

stiffness above 15 for high load inertia.