Chapter

Ⅳ

Tool Nose Radius Compensation

177

Ⅰ

Programming

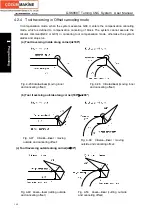

Fig.4-70 changing compensation value

(b) Positive/negative compensation value and tool nose center path

When the compensation value is negative (-), G41 and G42 exchange in programming. When

the tool center moves along the workpiece outer, it moves along the inner, and vice versa.

Note: The compensation value is equal to the offset value adding the wear value. When the compensation

sign is changed, the tool nose offset direction changes but the imaginary tool nose direction does not

change. So, do not change the compensation sign optionally.

z

End point of programmed arc is not in the arc

In the radius compensation process, when the system uses IJK to specify the circle center and

the end point of the arc is not in the arc, the system positions again the circle center position specified

by IJK, and confirms the circle center position according to the radius counted by IJK to execute the

radius compensation. When the counted radius is too small not to reach the end point of the arc, No.

254 alarm creates.

Note: At the moment, there is a difference between the counted arc and the specified in programming, and the

function is sued to regulate the error of the radius out-of-tolerance in some range in programming.

Fig. 4-71 End point of programmed arc be not in the arc

z

Continuous 3 or more than 3 blocks non-movement command

In tool radius compensation process, when there are 3 or 3 blocks without movement command,

the tool nose center reaches the end point of the last block and is vertical with programmed path

position of the last, at the moment, which causes the overcut, and the programmer should pay more

attention it.

General non-movement command

:

1. M03S300 only have M, S, T, F, O, N codes

2. #100=3 non-NC statement

(

when 6000#5 SBM is set to 1

)

Содержание 988T

Страница 6: ...GSK988T Turning CNC System User Manual VI ...

Страница 14: ...GSK988T Turning CNC System User Manual XIV ...

Страница 15: ...Chapter 1 Programming Fundamentals 1 Ⅰ Programming Ⅰ PROGRAMMING ...

Страница 16: ...GSK988T Turning CNC System User Manual 2 Ⅰ Programming ...

Страница 194: ...GSK988T Turning CNC System User Manual 180 Ⅰ Programming ...

Страница 195: ...Chapter Ⅰ Overview 181 Ⅱ Operation Ⅱ OPERATION ...

Страница 196: ...GSK988T Turning CNC System User Manual 182 Ⅱ Operation ...

Страница 215: ...Chapter Ⅲ Windows 201 Ⅱ Operation Note It can be displayed after U disk is inserted in the U disk catalog ...

Страница 217: ...Chapter Ⅲ Windows 203 Ⅱ Operation ...

Страница 267: ...Chapter Ⅲ Windows 253 Ⅱ Operation Fig 3 51 Fig 3 52 ...

Страница 412: ...GSK988T Turning CNC system User Manual 398 Appendix Fig 3 5 Horizontal operation panel appearance dimension ...