GSK988T Turning CNC System User Manual

160

Ⅰ

Programming

non-movement command.

Note 7: The system does not execute the tool nose radius compensation in G50, G52, G32, G34, G92, G71,

G72, G73, G74, G75, G76 and temporarily cancels the compensation mode. Before the system

temporarily cancels the compensation execution and when the system modal is G02 or G03, No.262

alarms.

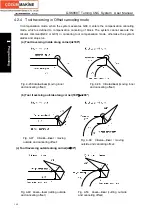

Note 8: In G40, for the inner or outer machining, the system moves to the intersection of two paths, and

executes the tool nose radius compensation cancel here, and then moves to the target point after the

cancel. When there is no intersection and the tool reaches the normal line position of the end point of

the last block, the system cancels the tool nose radius compensation and then moves the target

point after the cancel. At the moment, the overcut creates, the workpiece must not be machined.

Note 9: In tool nose radius compensation mode, the system must not be switched to other levels, otherwise,

No.253 alarms.

Note 10: In tool nose radius compensation mode, the system cancels the tool compensation mode in RESET,

M30 or M02 mode.

Note 11: In MDI mode, the system cannot execute the tool nose radius compensation creation and its cancel.

When the system specifies the tool nose radius compensation command, it executes the command

according to No.5008 Bit4(MCR). When the parameter is set to 1, the system alarms.

4.1.7 Application

Machine a workpiece in the front tool post coordinate system as Fig. 4-14. Tool number:

T0101, tool nose radius R=2, imaginary tool nose number T=3.

X

Z

R6

Fig. 4-14

Set the correct imaginary tool nose direction for executing the toolsetting in offset cancel

mode, Set the tool nose radius R and imaginary tool nose direction in “

TOOL OFFSET & WEAR”

window as following:

Table 4-3

No.

X

Z

Y … R T

001 …

2.000 3

002 … … … … … …

… … … … … … …

007 … … … … … …

Program:

G00 X100 Z50 M3 T0101 S600; (Position, start spindle, tool change and execute tool

compensation)

G42 G00 X0 Z3; (Set tool nose radius compensation)

Содержание 988T

Страница 6: ...GSK988T Turning CNC System User Manual VI ...

Страница 14: ...GSK988T Turning CNC System User Manual XIV ...

Страница 15: ...Chapter 1 Programming Fundamentals 1 Ⅰ Programming Ⅰ PROGRAMMING ...

Страница 16: ...GSK988T Turning CNC System User Manual 2 Ⅰ Programming ...

Страница 194: ...GSK988T Turning CNC System User Manual 180 Ⅰ Programming ...

Страница 195: ...Chapter Ⅰ Overview 181 Ⅱ Operation Ⅱ OPERATION ...

Страница 196: ...GSK988T Turning CNC System User Manual 182 Ⅱ Operation ...

Страница 215: ...Chapter Ⅲ Windows 201 Ⅱ Operation Note It can be displayed after U disk is inserted in the U disk catalog ...

Страница 217: ...Chapter Ⅲ Windows 203 Ⅱ Operation ...

Страница 267: ...Chapter Ⅲ Windows 253 Ⅱ Operation Fig 3 51 Fig 3 52 ...

Страница 412: ...GSK988T Turning CNC system User Manual 398 Appendix Fig 3 5 Horizontal operation panel appearance dimension ...