GSK988T Turning CNC System User Manual

58

Ⅰ

Programming

Command function:

commanding G52 in the program can set the local coordinate system in

the workpiece coordinate system G54~G59. The origin of the local coordinate

system can set in the position specified by IP_ in the workpiece coordinate

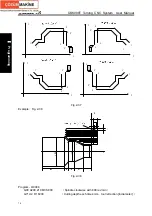

system. The corresponding relationship is as Fig. 2-26.

Fig. 2-26

Command explanation:

G52 is non-modal;

IP_: when IP_ is absolute command, the system specifies the

absolute coordinate value of origin of local coordinate system in the

workpiece coordinate system; when IP_ is the incremental

command, the system specifies the relative coordinate value of the

origin of the local coordinate system related to the one of the

workpiece coordinate system;

Once the local coordinate system is created, its coordinates are

used to the axis motion command. Using G52 to command the zero

of the new local coordinate system( workpiece coordinate system)

can change the position of the local coordinate system;

Making the zero of the local coordinate system coincide with the

one of the workpiece coordinate system can cancel the local

coordinate system and returns to the workpiece coordinate system,

i.e. command G52 X0 Z0.

Note 1: The local coordinate system setting does not change the workpiece coordinate system and

the machine coordinate system.

Note 2: Commanding G52 can temporarily cancel the offset in the tool nose radius compensation.

Note 3: In local coordinate system, when G50 sets the workpiece coordinate system and the system

has not specified the coordinate values to all axes in the local coordinate system, the axis

which is not specified in G50 in the local coordinate system still keeps, the local coordinate

system corresponding to G50 axis is cancelled; For example:

……

G52 X50 Z50;

……

G50 X100; at the moment, Z coordinate value is not change, the local coordinate system

corresponding to X is cancelled

……

Note 4: When the system selects the workpice coordinate system command

(

G54

~

G59

)

to change

the workpiece coordinate system in the local coordinate system, the local coordinate system

also moves to the new workpiece coordinate system.

Note 5: Whether the local coordinate system in reset is cancelled is determined by No.1202 Bit

3(RLC) , the local coordinate system is cancelled in reset when the parameter is set to 1.

Note 6: Whether the local coordinate system in manual reference position return is cancelled is

determined by No.1201Bit 2 (ZCL), the local coordinate system is cancelled in manual

Содержание 988T

Страница 6: ...GSK988T Turning CNC System User Manual VI ...

Страница 14: ...GSK988T Turning CNC System User Manual XIV ...

Страница 15: ...Chapter 1 Programming Fundamentals 1 Ⅰ Programming Ⅰ PROGRAMMING ...

Страница 16: ...GSK988T Turning CNC System User Manual 2 Ⅰ Programming ...

Страница 194: ...GSK988T Turning CNC System User Manual 180 Ⅰ Programming ...

Страница 195: ...Chapter Ⅰ Overview 181 Ⅱ Operation Ⅱ OPERATION ...

Страница 196: ...GSK988T Turning CNC System User Manual 182 Ⅱ Operation ...

Страница 215: ...Chapter Ⅲ Windows 201 Ⅱ Operation Note It can be displayed after U disk is inserted in the U disk catalog ...

Страница 217: ...Chapter Ⅲ Windows 203 Ⅱ Operation ...

Страница 267: ...Chapter Ⅲ Windows 253 Ⅱ Operation Fig 3 51 Fig 3 52 ...

Страница 412: ...GSK988T Turning CNC system User Manual 398 Appendix Fig 3 5 Horizontal operation panel appearance dimension ...