GSK988T Turning CNC System User Manual

286

Ⅱ

Operation

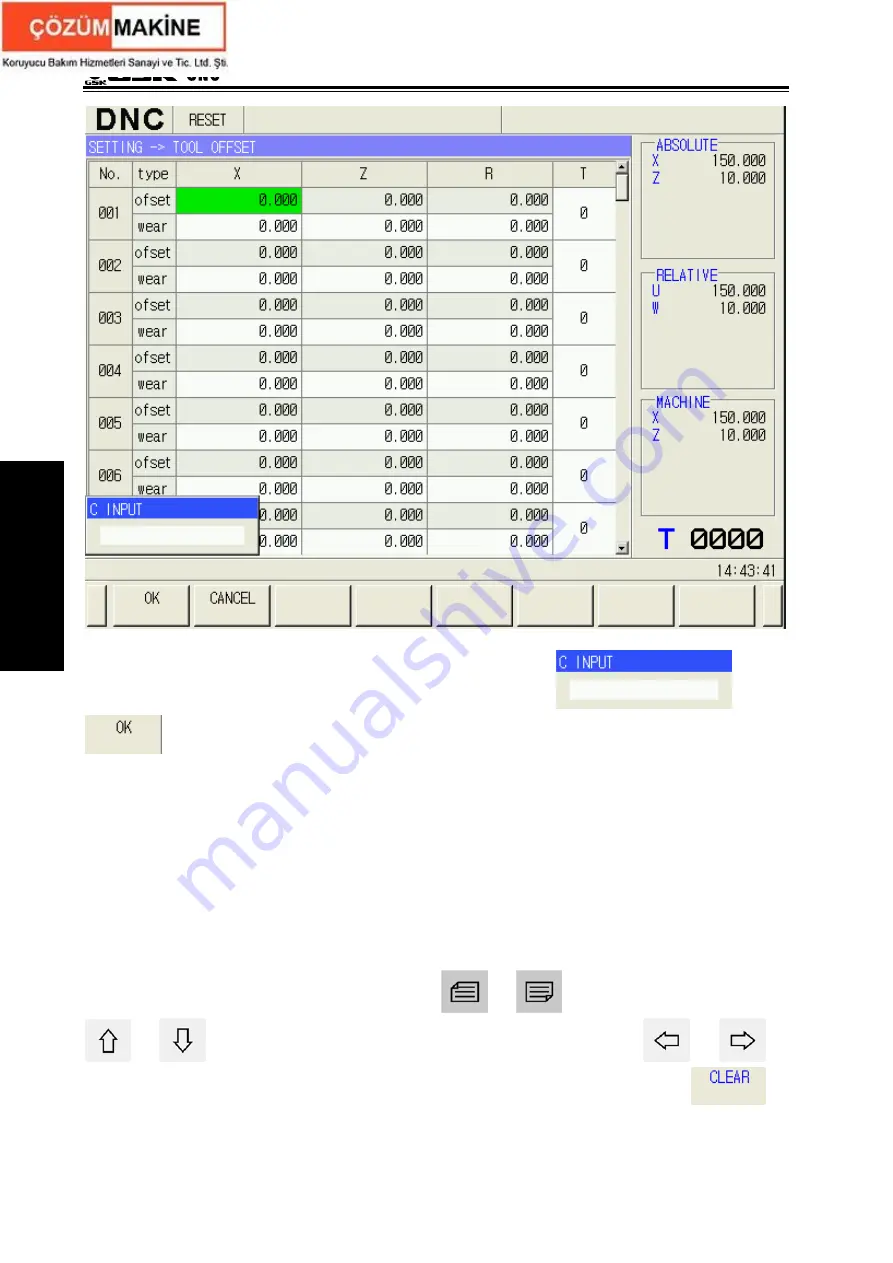

Fig.7-5

(

5

)

Input the coordinate axis name to be measured in

, press

for in-position measuring;

(

6

)

Then, calculate the offset value;

Press C input button to input the axial number.

If the cursor is on the tool offset box, the tool wearing value remains unchanged, write in the tool

offset value = the relative coordinate value – the tool wearing value;

If the cursor is on the tool wearing box, the tool offset value remains unchanged, write in the tool

wearing value = the relative coordinate value – the tool offset value.

7.1.5 Clearing the offset value or the wearing value

On the tool offset management window, press

or

to select the window, and press

or

to select the tool offset number to be rewritten, and press

or

to

select the tool offset Value, the wearing value or the tool number to be cleared; press

to

clear the selected tool offset value, the wearing value or the assumed tool nose direction number

relative to the axis.

Содержание 988T

Страница 6: ...GSK988T Turning CNC System User Manual VI ...

Страница 14: ...GSK988T Turning CNC System User Manual XIV ...

Страница 15: ...Chapter 1 Programming Fundamentals 1 Ⅰ Programming Ⅰ PROGRAMMING ...

Страница 16: ...GSK988T Turning CNC System User Manual 2 Ⅰ Programming ...

Страница 194: ...GSK988T Turning CNC System User Manual 180 Ⅰ Programming ...

Страница 195: ...Chapter Ⅰ Overview 181 Ⅱ Operation Ⅱ OPERATION ...

Страница 196: ...GSK988T Turning CNC System User Manual 182 Ⅱ Operation ...

Страница 215: ...Chapter Ⅲ Windows 201 Ⅱ Operation Note It can be displayed after U disk is inserted in the U disk catalog ...

Страница 217: ...Chapter Ⅲ Windows 203 Ⅱ Operation ...

Страница 267: ...Chapter Ⅲ Windows 253 Ⅱ Operation Fig 3 51 Fig 3 52 ...

Страница 412: ...GSK988T Turning CNC system User Manual 398 Appendix Fig 3 5 Horizontal operation panel appearance dimension ...