Chapter

Ⅱ

G Commands

59

Ⅰ

Programming

reference position return when the parameter is set to 1.

2.13.5 Level selection command G17

~

G19

Command function:

The level selection command is used to the arc interpolation and the

tool nose radius compensation selection level. Once the system has

selected the level, it can execute the arc interpolation and tool nose

radius compensation on the level.

Command format:

G17 selects XpYp level;

G18 selects ZpXp level;

G19 selects YpZp level;

Command explanation:

G17, G18, G19 are modal G commands.

Xp: X or its parallel axis

Yp: Y or its parallel axis

Zp: Z or its parallel axis

Note 1: Xp, Yp, Zp are determined by the axis addresses of G17, G18, G19 in the block; when the axis

addresses are omitted, the system defaults the omitted are the addresses of the basic axis; the

level keeps when the system does not command G17, G18, G19 blocks.

Note 2: The parameter sets each axis to have three basic axes (X, Y, Z) or the parallel axis.

Note 3: The level remains unchanged in the G17, G18, G19 not be specified.

Note 4: When the system is turned on, its initialization is defaulted to G18 state, i.e. ZX level;

Note 5: When the system repetitively specifies G17

~

G19 in the same block, and No.3403 Bit 6(AD2) is 0,

the last G17

~

G19 word is valid, the system alarms when the parameter is set to 1;

Note 6: The multi-compound cycle command

(

G70

~

G76

)

and the fixed cycle command

(

G90, G92, G94

)

are used to ZX basic axis level; when their functions are specified in other levels, the system

alarms;

Note 7: The motion command is not related to the level selection, besides the arc interpolation and tool

nose radius compensation command, when the system commands the axis beyond the levels, it

does not alarm and the axis can move; when the system selects the axis motion beyond the level

in the arc interpolation command, the system alarms. For example:

……;

G17;

G01 X100 Y50 Z20 F100; the system does not alarm, Z moves

……;

G02 X20 Z50 R100; the system alarms

……;

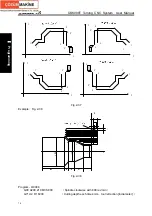

Example: the level selection: when X and A are parallel axis:

G17 X_ Y_

;

select XY level

G17 A_ Y_

;

select AY level

G18 X_ Z_

;

select ZX level

G17

;

select XY level

G17 A_ select AY level

G18 Y_ select ZX level, Y motion is not relative the level

2.13.6 Exact stop mode G61/cutting mode G64

G61 function: After programmed axis of the block must exactly stop at the end pont of the

block, the next block is executed.

G64 function: When the programmed axis of each block following G64 starts to develerate (it

has not reached the programmed end point), the system starts to execute

Содержание 988T

Страница 6: ...GSK988T Turning CNC System User Manual VI ...

Страница 14: ...GSK988T Turning CNC System User Manual XIV ...

Страница 15: ...Chapter 1 Programming Fundamentals 1 Ⅰ Programming Ⅰ PROGRAMMING ...

Страница 16: ...GSK988T Turning CNC System User Manual 2 Ⅰ Programming ...

Страница 194: ...GSK988T Turning CNC System User Manual 180 Ⅰ Programming ...

Страница 195: ...Chapter Ⅰ Overview 181 Ⅱ Operation Ⅱ OPERATION ...

Страница 196: ...GSK988T Turning CNC System User Manual 182 Ⅱ Operation ...

Страница 215: ...Chapter Ⅲ Windows 201 Ⅱ Operation Note It can be displayed after U disk is inserted in the U disk catalog ...

Страница 217: ...Chapter Ⅲ Windows 203 Ⅱ Operation ...

Страница 267: ...Chapter Ⅲ Windows 253 Ⅱ Operation Fig 3 51 Fig 3 52 ...

Страница 412: ...GSK988T Turning CNC system User Manual 398 Appendix Fig 3 5 Horizontal operation panel appearance dimension ...