GSK988T Turning CNC System User Manual

176

Ⅰ

Programming

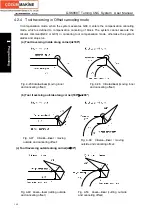

Fig.4-68 machining an inner sidestep less than 90°

z

Corner motion

When two or more than movement vector in the end point of one block create, the tool

moves to another vector from the vector linear, which is called the corner motion. When the

single block is valid, the tool stops in the last vector.

When two vectors coincide, the system does not execute the corner motion and the second

vector will be ignored. When the two-axis increments of the movement vector in the

compensation level are less than the setting values of No. 5010(CLV), the second vector is

ignored, but it is not ignored when the interpolation block is the arc.

Fig. 4-69 corner motion

z

Changing compensation value

(a) The system executes the tool change in the compensation cancel mode, the compensation

value is changed. When the compensation value is changed in the compensation mode,

No.5001 Bit4(EVR) can set whether the compensation value change is valid from the nest T

command or the next buffer block.

Содержание 988T

Страница 6: ...GSK988T Turning CNC System User Manual VI ...

Страница 14: ...GSK988T Turning CNC System User Manual XIV ...

Страница 15: ...Chapter 1 Programming Fundamentals 1 Ⅰ Programming Ⅰ PROGRAMMING ...

Страница 16: ...GSK988T Turning CNC System User Manual 2 Ⅰ Programming ...

Страница 194: ...GSK988T Turning CNC System User Manual 180 Ⅰ Programming ...

Страница 195: ...Chapter Ⅰ Overview 181 Ⅱ Operation Ⅱ OPERATION ...

Страница 196: ...GSK988T Turning CNC System User Manual 182 Ⅱ Operation ...

Страница 215: ...Chapter Ⅲ Windows 201 Ⅱ Operation Note It can be displayed after U disk is inserted in the U disk catalog ...

Страница 217: ...Chapter Ⅲ Windows 203 Ⅱ Operation ...

Страница 267: ...Chapter Ⅲ Windows 253 Ⅱ Operation Fig 3 51 Fig 3 52 ...

Страница 412: ...GSK988T Turning CNC system User Manual 398 Appendix Fig 3 5 Horizontal operation panel appearance dimension ...