Chapter

Ⅱ

G Commands

33

Ⅰ

Programming

X20 Z30

;

(

rapidly traverse to X20 Z30

;

the modal G0 can be omitted

)

G1 X50 Z50 F300

;

(

linear interpolation to X50 Z50

,

300mm/min

;

the modal G1 is

valid

)

X100

;

(

linear interpolation to X100 Z50

,

300mm/min

;

When Z coordinate

is not input, the current coordinate value Z50 is used; F300 is

kept, G01 can be omitted when it is modal.

)

G0 X0 Z0

;

(

rapidly traverse to X0 Z0

,

the modal G0 is valid

)

M30

;

2.1.3 Related definitions

Definitions of word are as follows except for the especial explanations:

Starting point: position before the current block runs;

End point: position after the current block ends;

X:

X absolute coordinates of end point;

Xp

:

absolute coordinate of X end point or one which is parallel to X;

U:

different value of X absolute coordinate between starting point and end point;

Y

:

Y absolute coordinate of end point;

Yp

:

absolute coordinate of Y end point or one which is parallel to Y;

V

:

different value of Y absolute coordinate;

Z:

Z absolute coordinates of end point;

Zp

:

absolute coordinate of Z end point or one which is parallel to Z;

W:

different value of absolute coordinates between starting point and end point;

C

:

C absolute coordinate of end point;

H

:

different value of C absolute coordinate between end point and starting point;

A

:

A absolute coordinate of end point;

B

:

B absolute coordinate of end point;

F

:

cutting feedrate.

IP

:

it is the combination of axes to execute the data provided by G command, the later

specified address is valid when the absolute address and relative address of one

axis are defined and are in the same block to be edit. The range for each axis in

corresponding parameter is as follows:

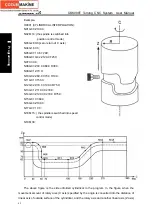

2.2 Rapid Traverse (Positioning) G00

Command function: I

n the absolute command, the tool rapidly traverses to the position

specified by the workpiece coordinate system; in the incremental

command, the tool rapidly traverses to the position which offsets the

specified value of the current position.

Command format

:

G00 IP__

;

Command explanation:

IP: it is the end point coordinate value of the tool traversing for the

absolute command; it is the tool traversing distance for the incremental

command.

Содержание 988T

Страница 6: ...GSK988T Turning CNC System User Manual VI ...

Страница 14: ...GSK988T Turning CNC System User Manual XIV ...

Страница 15: ...Chapter 1 Programming Fundamentals 1 Ⅰ Programming Ⅰ PROGRAMMING ...

Страница 16: ...GSK988T Turning CNC System User Manual 2 Ⅰ Programming ...

Страница 194: ...GSK988T Turning CNC System User Manual 180 Ⅰ Programming ...

Страница 195: ...Chapter Ⅰ Overview 181 Ⅱ Operation Ⅱ OPERATION ...

Страница 196: ...GSK988T Turning CNC System User Manual 182 Ⅱ Operation ...

Страница 215: ...Chapter Ⅲ Windows 201 Ⅱ Operation Note It can be displayed after U disk is inserted in the U disk catalog ...

Страница 217: ...Chapter Ⅲ Windows 203 Ⅱ Operation ...

Страница 267: ...Chapter Ⅲ Windows 253 Ⅱ Operation Fig 3 51 Fig 3 52 ...

Страница 412: ...GSK988T Turning CNC system User Manual 398 Appendix Fig 3 5 Horizontal operation panel appearance dimension ...