GSK988T Turning CNC System User Manual

48

Ⅰ

Programming

#5065, its last bit digit corresponds to the No. n axis of the system), at the same time,

the movement in G31 block ends. No. 6200 Bit 19SK0) sets the invalid input state of

the skip signal, and when it is set to 0, the input signal 1 is valid.

Operation: When the skip signal becomes “1”, CNC executes as follows: When the block is

executing G31, CNC stores the current absolute coordinates for each axis. CNC

stops G31 to execute the next block, the skip signal detects its state instead of its

RISING EDGE. So when the skip signal is “1”, it meets the skip conditions.

Note1: When the skip signal is input, the feedrate override, the dry run, and automatic acceleration/

deceleration are invalid in the course of movement by the skip function, which is to improve the

tool positioning precision.

Note 2: The skip signal is valid, the system immediately stops the feed axis (without acceleration/

deceleration execution), and G31 feedrate should be as low as possible to get the precise stop

position.

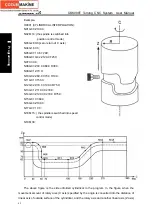

2.11 Automatic Tool Offset G36, G37

Command function:

When the command is executed to make the tool move to the measured

position, the CNC automatically measures the difference between the

current actual coordinates and the command coordinates to be the tool

offset value. The function is used to the automatic toolsetting.

Command format:

G36

X__;

G37 Z__;

Explanations:

X absolute coordinate(only used to G36), Z absolute coordinate (only used to

G37);

Non-modal G command (00 group);

Cancel the tool nose radius compensation before using it;

Only use the absolute programming;

Define the workpiece coordinate system before using the command;

Specify the tool number and tool compensation number before using the command;

Measure position arrival signal:

XAE(X3.6)

――――

corresponding to G36

ZAE(X3.7)

――――

corresponding to G37

Function:

When the position measured by the program command is different from that where the

tool actually reaches (i.e. at the time, the measured position arrival signal becomes “1”),

the difference of the coordinates is added to the current tool compensation value to

update the compensation value. When G36X_(or G37Z_) is executed, the tool firstly

rapidly traverses to the position measured by the command, and decelerates and

temporarily stop the position before the measured position, and then, reaches to the

measured position at the speed set by No.6241 (or No.6242). When the measured

position arrival signal corresponding to G command becomes the state set by No.

6240#0, and the tool is in the measured position range ±

ε

, the system updates the offset

compensation value and ends the block. When the measured position arrival signal

does not become “1”, and after the tool reaches the measured position distance

ε

, the

Содержание 988T

Страница 6: ...GSK988T Turning CNC System User Manual VI ...

Страница 14: ...GSK988T Turning CNC System User Manual XIV ...

Страница 15: ...Chapter 1 Programming Fundamentals 1 Ⅰ Programming Ⅰ PROGRAMMING ...

Страница 16: ...GSK988T Turning CNC System User Manual 2 Ⅰ Programming ...

Страница 194: ...GSK988T Turning CNC System User Manual 180 Ⅰ Programming ...

Страница 195: ...Chapter Ⅰ Overview 181 Ⅱ Operation Ⅱ OPERATION ...

Страница 196: ...GSK988T Turning CNC System User Manual 182 Ⅱ Operation ...

Страница 215: ...Chapter Ⅲ Windows 201 Ⅱ Operation Note It can be displayed after U disk is inserted in the U disk catalog ...

Страница 217: ...Chapter Ⅲ Windows 203 Ⅱ Operation ...

Страница 267: ...Chapter Ⅲ Windows 253 Ⅱ Operation Fig 3 51 Fig 3 52 ...

Страница 412: ...GSK988T Turning CNC system User Manual 398 Appendix Fig 3 5 Horizontal operation panel appearance dimension ...