GSK988T Turning CNC System User Manual

74

Ⅰ

Programming

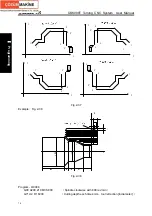

the starting point of finishing path (i.e. starting point of ns block)is the same these

of starting point and end point of G72, called A point; the first block of finishing

path(ns block)is used for Z rapid traversing or cutting feed, and the end point of

finishing path is called to B point; the end point of finishing path(end point of nf

block)is called to C point. The finishing path is A

→

B

→

C.

Roughing

path

The finishing path is the one after offsetting the finishing allowance

(

Δ

u,

Δ

w

)

and is

the path contour formed by executing G72. A, B, C point of finishing path after

offset corresponds separately to A’, B’, C’point of roughing path, and the final

continuous cutting path of G72 is B’

→

C’ point.

Δ

d

It is each travel of Z tool infeed in roughing without sign symbols, and the direction

of tool infeed is defined by move direction of ns block.

Δ

d is reserved after the

system executes W

(

Δ

d

)

and NO.5132 value is modified. The value of system

parameter NO.051 is regarded as the travel of tool infeed when W

(

Δ

d

)

is not input.

e

It is each travel of Z tool infeed in roughing without sign symbols, and the direction

of tool retraction is opposite to that of tool infeed; after R(e) is executed, e value e

is reserved and the system modifies No.5133 value. The value of system

parameter NO.5133 is regarded as the travel of tool retraction when R

(

e

)

is not

input.

ns

Block number of the first block of finishing path.

nf

Block number of the last block of finishing path.

Δ

u

X finishing allowance in roughing, (X coordinate offset of roughing path compared

to finishing path, i.e. the different value of X absolute coordinate between A’and A,

diameter value with sign symbols).

Δ

w

Z finishing allowance in roughing, its value: -9999.999~9999.999 ( Z coordinate

offset of roughing path compared to finishing path, i.e. the different value of X

absolute coordinates between A’ and A, with sign symbols).

F

Cutting feedrate; S: Spindle speed; T: Tool number, tool offset number.

M, S, T, F

They can be specified in the first G72 or the second ones or program ns

~

nf. M, S,

T, F functions of M, S, T, F blocks are invalid in G72, and they are valid in G70

finishing blocks.

Address Incremental

system

Metric

(

mm

)

input

Inch (inch) input

ISB system

0.001~99999.999

0.0001~9999.9999

W

(

Δ

d

)

ISC system

0.0001~9999.9999

0.00001~999.99999

ISB system

0

~

99999.999

0

~

9999.9999

R

(

e

)

ISC system

0

~

9999.9999

0

~

999.99999

ISB system

-99999.999

~

99999.999 -9999.9999

~

9999.9999

U

(

Δ

u

)

ISC system

-9999.9999

~

9999.9999

-999.99999

~

999.99999

ISB system

-99999.999

~

99999.999

-9999.9999

~

9999.9999

W

(

Δ

w

)

ISC system

-9999.9999

~

9999.9999

-999.99999

~

999.99999

ISC system

1

~

99999

1

~

99999

P

(

ns

)

ISC system

1

~

99999

1

~

99999

Q

(

nf

)

ISC system

1

~

99999

1

~

99999

Содержание 988T

Страница 6: ...GSK988T Turning CNC System User Manual VI ...

Страница 14: ...GSK988T Turning CNC System User Manual XIV ...

Страница 15: ...Chapter 1 Programming Fundamentals 1 Ⅰ Programming Ⅰ PROGRAMMING ...

Страница 16: ...GSK988T Turning CNC System User Manual 2 Ⅰ Programming ...

Страница 194: ...GSK988T Turning CNC System User Manual 180 Ⅰ Programming ...

Страница 195: ...Chapter Ⅰ Overview 181 Ⅱ Operation Ⅱ OPERATION ...

Страница 196: ...GSK988T Turning CNC System User Manual 182 Ⅱ Operation ...

Страница 215: ...Chapter Ⅲ Windows 201 Ⅱ Operation Note It can be displayed after U disk is inserted in the U disk catalog ...

Страница 217: ...Chapter Ⅲ Windows 203 Ⅱ Operation ...

Страница 267: ...Chapter Ⅲ Windows 253 Ⅱ Operation Fig 3 51 Fig 3 52 ...

Страница 412: ...GSK988T Turning CNC system User Manual 398 Appendix Fig 3 5 Horizontal operation panel appearance dimension ...