1. FUNCTIONS AND CONFIGURATION

1 - 15

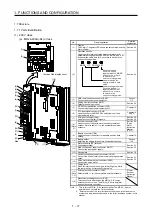

Function Description

Detailed

explanation

Output signal selection

(device settings)

The output devices including MBR (Electromagnetic brake interlock) can be assigned

to certain pins of the CN1 connector.

[Pr. PD23] to

[Pr. PD28]

Output signal (DO) forced

output

Output signal can be forced on/off independently of the servo status.

Use this function for checking output signal wiring, etc.

Section 4.5.8

Restart after instantaneous

power failure

If the input power supply voltage had reduced to cause an alarm but has returned to

normal, the servo motor can be restarted by merely switching on the start signal.

(available in the future)

Command pulse selection

Command pulse train form can be selected from among three different types.

[Pr. PA13]

Torque limit

Servo motor torque can be limited to any value.

Section 3.6.1

(5)

[Pr. PA11]

[Pr. PA12]

Speed limit

Servo motor speed can be limited to any value.

Section 3.6.3

(3)

[Pr. PC05] to

[Pr. PC11]

Status display

Servo status is shown on the 5-digit, 7-segment LED display

Section 4.5

External I/O signal display

On/off statuses of external I/O signals are shown on the display.

Section 4.5.7

Automatic VC offset

Voltage is automatically offset to stop the servo motor if it does not come to a stop

when VC (Analog speed command) or VLA (Analog speed limit is 0 V.

Section 4.5.4

Alarm code output

If an alarm has occurred, the corresponding alarm number is outputted in 3-bit code.

Chapter 8

Test operation mode

Jog operation, positioning operation, motor-less operation, DO forced output, and

program operation

MR Configurator2 is required to perform positioning operation or program operation.

Section 4.5.9

Analog monitor output

Servo status is output in terms of voltage in real time.

[Pr. PC14],

[Pr. PC15]

MR Configurator2

Using a personal computer, you can perform the parameter setting, test operation,

monitoring, and others.

Section 11.7

Linear servo system

Linear servo system can be configured using a linear servo motor and liner encoder.

This is used with servo amplifiers with software version A5 or later. Check the

software version of the servo amplifier using MR Configurator2.

Chapter 15

Direct drive

servo system

The direct drive servo system can be configured to drive a direct drive motor.

This is used with servo amplifiers with software version A5 or later. Check the

software version of the servo amplifier using MR Configurator2.

Chapter 16

Fully closed loop system

Fully closed loop system can be configured using the load-side encoder.

This is used with servo amplifiers with software version A5 or later. Check the

software version of the servo amplifier using MR Configurator2.

Chapter 17

One-touch tuning

Gain adjustment is performed just by one click on a certain button on MR

Configurator2 or operation section.

Section 6.1

Tough drive function

This function makes the equipment continue operating even under the condition that

an alarm occurs.

The tough drive function includes two types: the vibration tough drive and the

instantaneous power failure tough drive.

Section 7.3

Drive recorder function

This function continuously monitors the servo status and records the status transition

before and after an alarm for a fixed period of time. You can check the recorded data

on the drive recorder window on MR Configurator2 by clicking the "Graph" button.

However, the drive recorder will not operate on the following conditions.

1. You are using the graph function of MR Configurator2.

2. You are using the machine analyzer function.

3. [Pr. PF21] is set to "-1".

[Pr. PA23]

STO function

This function is a functional safety that complies with IEC/EN 61800-5-2. You can

create a safety system for the equipment easily.

Chapter 13

Servo amplifier life diagnosis

function

You can check the cumulative energization time and the number of on/off times of the

inrush relay. This function gives an indication of the replacement time for parts of the

servo amplifier including a capacitor and a relay before they malfunction.

MR Configurator2 is necessary for this function.

Power monitoring function

This function calculates the power running energy and the regenerative power from

the data in the servo amplifier such as speed and current. Power consumption and

others are displayed on MR Configurator2.

Machine diagnosis function

From the data in the servo amplifier, this function estimates the friction and vibrational

component of the drive system in the equipment and recognizes an error in the

machine parts, including a ball screw and bearing.

MR Configurator2 is necessary for this function.

Summary of Contents for MR-J4-100A

Page 9: ...A 8 MEMO ...

Page 61: ...1 FUNCTIONS AND CONFIGURATION 1 44 MEMO ...

Page 67: ...2 INSTALLATION 2 6 MEMO ...

Page 137: ...3 SIGNALS AND WIRING 3 70 MEMO ...

Page 261: ...6 NORMAL GAIN ADJUSTMENT 6 24 MEMO ...

Page 291: ...7 SPECIAL ADJUSTMENT FUNCTIONS 7 30 MEMO ...

Page 299: ...8 TROUBLESHOOTING 8 8 MEMO ...

Page 319: ...9 OUTLINE DRAWINGS 9 20 MEMO ...

Page 461: ...12 ABSOLUTE POSITION DETECTION SYSTEM 12 36 MEMO ...

Page 511: ...14 COMMUNICATION FUNCTION 14 38 MEMO ...

Page 559: ...16 USING A DIRECT DRIVE MOTOR 16 20 MEMO ...

Page 583: ...17 FULLY CLOSED LOOP SYSTEM 17 24 MEMO ...

Page 621: ...APPENDIX App 38 ...

Page 639: ......