Chapter 7

7-9

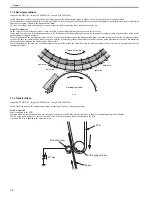

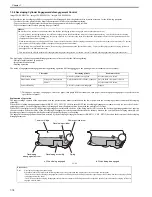

7.2.3 D-half Control

0019-5021

imageCLASS MF9170c / imageCLASS MF9150c / imageCLASS MF8450c

This control corrects the gradation data based on the halftone density in order to obtain ideal image gradation.

The DC controller executes this control following the command sent from the main controller.

Explanation of operation

1) When receiving a command of executing density measurement from the main controller, the DC controller forms a pattern image for image gradation correction

for each color on the ETB.

The pattern image for image gradation correction is formed with the specified density for each color (low at the left side and high at the right side), using the

optimum developing bias determined by the environment related corrective control.

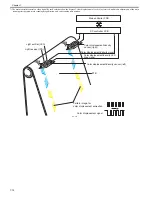

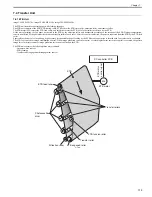

2) The DC controller sends a color displacement/density LED drive signal and flashes the light emitter (LED) of the color displacement/density sensor.

The color displacement/density sensor is a reflection type sensor located on the upper side of the ETB. It consists of the light emitter (LED) and light receiver

(PD).

3) The light emitted from the light emitter is reflected at the pattern image for image gradation correction and received at the light receiver of the color displacement/

density sensor.

The intensity of the reflected light varies depending on the toner density.

4) The color displacement/density sensor converts the received light into a voltage, and sends it to the DC controller as a density detection signal (analog value).

5) The DC controller converts the received density detection signal into density data, and sends it to the main controller.

6) The main controller performs gradation correction based on the received density data in order to obtain an ideal halftone image.

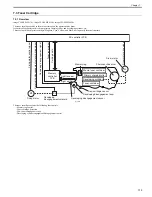

F-7-14

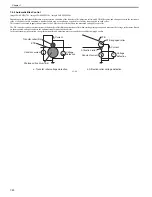

Error Codes:

E020

Warning: color displacement/density sensor abnormality

When light could not be received by the light receiver, the machine sets an initial value for the image density correction value and displays the error code

on the control panel.

ETB

Color displacement/density sensor (left)

Color displacement/density LED

drive signal

Color displacement/density

sensor (right)

Color displacement/density signal

Pattern image for image gradation correction

DC controller PCB

Main controller PCB

Light emitter (LED)

Light receiver (PD)

Summary of Contents for imageCLASS MF8450c

Page 16: ...Chapter 1 Introduction ...

Page 55: ...Chapter 2 Basic Operation ...

Page 61: ...Chapter 3 Main Controller ...

Page 75: ...Chapter 4 Original Exposure System ...

Page 88: ...Chapter 5 Original Feeding System ...

Page 105: ...Chapter 6 Laser Exposure ...

Page 113: ...Chapter 7 Image Formation ...

Page 150: ...Chapter 8 Pickup and Feed System ...

Page 184: ...Chapter 9 Fixing System ...

Page 200: ...Chapter 10 External and Controls ...

Page 230: ...Chapter 11 Maintenance and Inspection ...

Page 233: ...Chapter 12 Measurement and Adjustments ...

Page 237: ...Chapter 13 Correcting Faulty Images ...

Page 260: ...Chapter 14 Error Code ...

Page 272: ...Chapter 15 Special Management Mode ...

Page 280: ...Chapter 16 Service Mode ...

Page 322: ...Chapter 17 Upgrading ...

Page 327: ...Chapter 17 17 4 3 Click Next F 17 4 4 Select a USB connected device and click Next F 17 5 ...

Page 328: ...Chapter 17 17 5 5 Click Start F 17 6 6 Click Yes F 17 7 Download will be started F 17 8 ...

Page 330: ...Chapter 18 Service Tools ...

Page 334: ...Appendix ...

Page 349: ......