152

6.3. Speed control mode

Speed control mode is suitable for precise speed control applications, such as and CNC

machines, drilling machine, etc. There are two types of command sources: (1) analog input,

(2)

internal register.

The analog command controls the motor speed by external voltage input.

The register input controls the speed in two methods.

The first method is to manually set the 7 different required speeds in the 7 command registers

(PC05~PC11) before starting the operation, and then switch DI of SP1, SP2, SP3 of CN1.

The second method is to changes the value in the register through communication software

with RS485 or USB.

To deal with the problem of non-continuous speed when switching registers, you can use the

S-curve function, thus the motor can keep running smoothly when switching to different speed.

In a closed-loop system, the servo drive uses gain adjustment and the accumulative integrated

PI controller. And it also provides two operation modes (manual and automatic).

In manual mode, you can set all the parameters, so all the auto or auxiliary functions are

disabled. In auto gain adjustment modes, the servo drive performs load inertia estimation and

provides parameter adjustment function. In this case, the parameter setting values are

regarded as the initial values. This simple mode provides a robust system function for the user,

which is different from the adaptability rule that requires a longer learning time in the automatic

operation mode. Simple operation mode can suppress external load interference and

mechanism resonance in real time, and tolerate load inertia change.

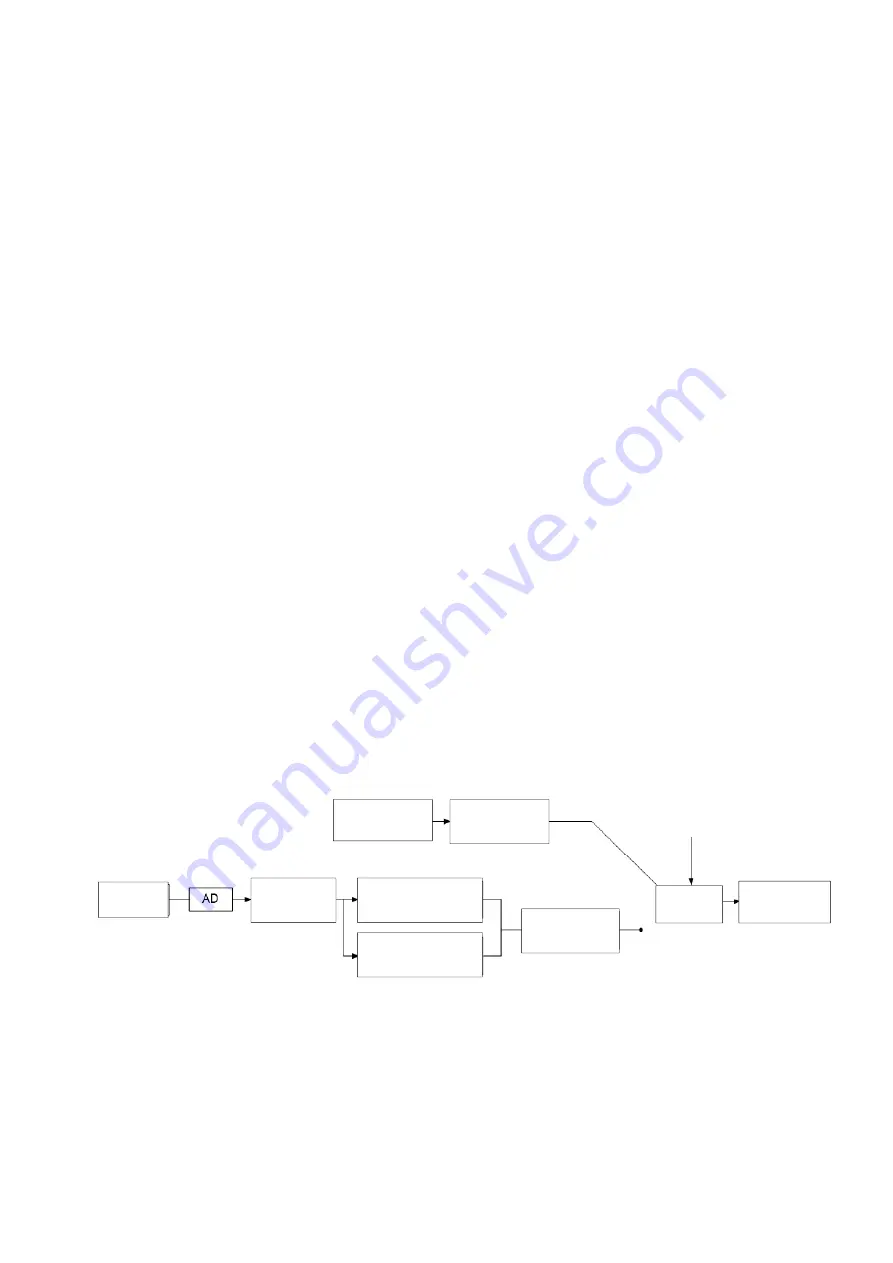

Analog

signal

Speed linear

voltage filter

(PC36)

Analog command

speed max output

(PC12)

Speed limit offset

(PC26)

S-type smoother

(PC01~PC03)

S-type smoother

(PC01~PC03)

Inner speed

command

(PC05~PC11)

SP1-SP3 signal

CN1

Control mode

option (PA01)

speed filter constant

(PB21)

The upper part of the graph is the internal speed command, which controls the speed

command by manually input parameter and switches by terminal DI. The lower part of the

graph is the external analog input ±10V voltage. After processing by A/D, it calculates the set

analog command max output(scaling) and voltage offset value and then outputs to the next

part.

Содержание SDP Series

Страница 33: ...20 400V series DC 24V Power supply Note terminal P N cannot be grounded ...

Страница 42: ...29 2 CN1 connector male Front view Side view Rear view CN1 wiring terminal on the back of CN1 1 26 50 25 ...

Страница 45: ...32 4 The last step is to fasten the screw of housing ...

Страница 203: ...190 It is recommended that the user performs torque position mode switching after motor is stopped completely ...

Страница 385: ...372 ...

Страница 405: ...392 ...

Страница 499: ...486 SME L040 SME L075 SME L100 SME L150 ...

Страница 500: ...487 SME L200 SME L300 SME M100 SME M150 ...

Страница 509: ...496 When the load reaches 300 the operation time is 5 51 seconds ...

Страница 541: ...528 Middle inertia power cable Middle inertia 2KW 3KW 400V High inertia power cable 1 8KW 2 9KW 4 4KW 5 5KW 7 5KW ...

Страница 555: ...542 14 5 Manual version and revision history Manual version V1 00 Release month July 2022 ...