COPYRIGHT © 2001 CANON INC. CANON CLC1000/1000S/3100 REV.2 MAY 2001 PRINTED IN JAPAN (IMPRIME AU JAPON)

3-115

3. OPERATION AND TIMING

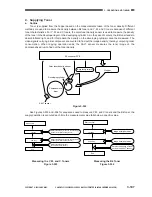

The current to the LED is controlled so that the direct intensity (level of REF-S-K) is constant, thereby

maintaining the intensity of the LED at a specific value.

Figure 3-544

When the developer has been replaced upon installation or a sensor has been replaced, set the initial

values for the reflected light and the direct light in service mode. (See chapter 7. Troubleshooting Image

Problems.) Then, the following takes place after a copying run:

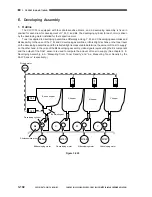

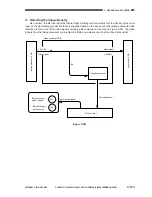

Figure 3-545

Detection of

direct light

Photosensitive

drum

Detection of

reflected light

LED

SGNL-S-K

LEDON*

REF-S-K

CPU

Toner

supply signal

Toner density signal

DC controller PCB

Q1

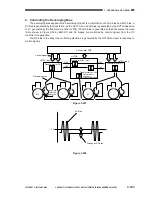

Corrects for dirt on the window.

During copying operation, the density is measured

with reference to video signals.

Computed based on the difference between

the reflected light and the initial value.

Various measurement data units may be checked

in service mode.

After copying operation, post rotation starts.

The transfer belt lowers.

A density pattern is formed

on the photosensitive drum.

LED turns ON.

The direct light signal and

the reflected light signal are read.

The light reflected by the

surface of the drum is read .

The toner density is

measured.

Initial values are set for the reflected light

and the direct light.

Performed when replacing the developer or sensors.

To prevent disrupting toner images.

Содержание Vizcam 1000

Страница 12: ......

Страница 30: ......

Страница 44: ......

Страница 86: ......

Страница 254: ......

Страница 372: ......

Страница 374: ......

Страница 418: ......

Страница 438: ......

Страница 442: ......

Страница 754: ......

Страница 764: ......

Страница 766: ......

Страница 840: ...0501GR PRINTED IN JAPAN IMPRIME AU JAPON This publication is printed on 100 reprocessed paper...