Chapter 4 Parameters

4-153

this way a system can be stable without steady-state fault by proportional gain control and integral

time control.

3. Differential control (D): the controller output is proportional to the differential of the controller input.

During elimination of the fault, oscillation or instability may occur. The differential control can be used

to suppress these effects by acting before the fault. That is, when the fault is near 0, the differential

control should be 0. Proportional gain (P) + differential control (D) can be used to improve the system

state during PID adjustment.

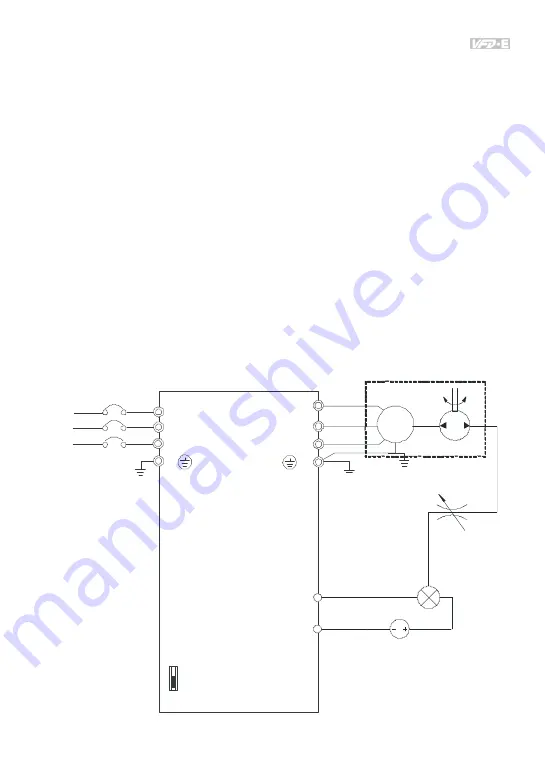

D. When PID control is used in a constant pressure pump feedback application:

Set the application’s constant pressure value (bar) to be the setpoint of PID control. The pressure

sensor will send the actual value as PID feedback value. After comparing the PID setpoint and PID

feedback, there will be a fault. Thus, the PID controller needs to calculate the output by using

proportional gain(P), integral time(I) and differential time(D) to control the pump. It controls the drive

to have different pump speed and achieves constant pressure control by using a 4-20mA signal

corresponding to 0-10 bar as feedback to the drive.

ACI/AVI

(4~20mA/0-10V)

ACM

U(T1)

V(T2)

W(T3)

IM

E

AV 2

I

ACI

VFD-E

R(L1)

S(L2)

T(L3)

(NFB)

R

S

T

E

DC

no fuse breaker

water pump

switch

analog signal common

feedback 4-20mA

corresponds to

0-10 bar

pressure

sensor

throttle