Chapter 1

1-6

[Caution]

- The density adjustment is performed based on all the density values of marks from 0 to 8. If all marks from 0 to 8 are shown on the test page, make sure to gauge

and enter the density values for all imprinted marks.

- If the marks 0 and 8 are not shown on the test page, gauge and enter the density values for all the imprinted marks from 1 to 7 and make sure that the density values

for the marks 0 and 8 are set to "0". If you enter the density values other than "0" for the marks 0 and 8, you cannot perform density adjustment precisely.

5) Press Output Test Page > "Start Printing". Test page 2 with marks from -7 to +6 after adjustment is output.

[Reference]

- The marks -7 and +6 may not be shown on the output test page 2, depending on the paper width.

- Although the mark -7 may be shown on the output test page 2, the numbers you can adjust values for are from -6 to +6. You cannot adjust values for -7.

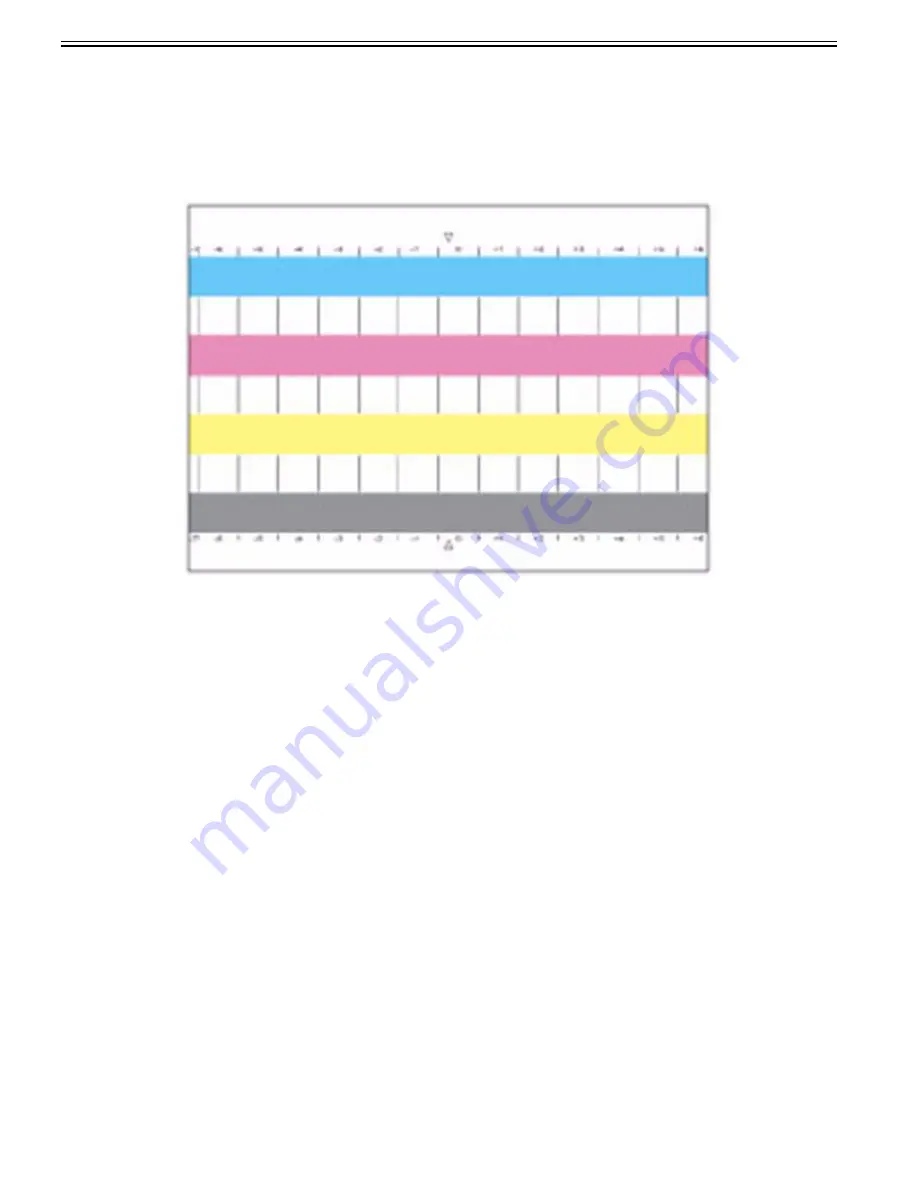

Test page 2

6) View the output test page 2 and confirm that there is no uneven density.

7) Press "Store and Finish".

b) To perform visual correction:

1) Settings/Registrations > Adjustment/Maintenance > Adjust Image Quality > Correct Shading > Visual Correction > Output Test Page > "Start Printing". Test

page 2 with marks from -7 to +6 is output.

[Reference]

- The marks -7 and +6 may not be shown on the output test page 2, depending on the paper width.

- Although the mark -7 may be shown on the output test page 2, the numbers you can adjust values for are from -6 to +6. You cannot adjust values for -7.

2) View the output test page > press "Fine Adjust" of the color you want to adjust.

3) Select the number to adjust > press "+" for a heavy density or "-" for a light density > "OK".

4) Press Output Test Page > "Start Printing". Test page 2 with marks from -7 to +6 after adjustment is output.

5) View the output test page 2 and confirm that there is no uneven density.

6) Press "Store and Finish".

7) The display returns to the screen of Correct Shading. Repeat steps for visual correction until the shading is improved.

c) To perform print server correction:

[Caution]

- "Print Server Correction" is displayed only when the imagePRESS Server is installed.

- For more information on the print server correction, see the instruction manual of the imagePRESS Server.

1) Settings/Registrations > Adjustment/Maintenance > Adjust Image Quality > Correct Shading > Print Server Correction > "Start Printing". Test page is output.

2) Gauge the mark on the output test page using the densitometer that is attached to the imagePRESS Server, and forward the adjustment values to the main unit.

3) Press Output Test Page > "Start Printing". Test page 2 with marks after adjustment based on the transferred data is output.

[Reference]

- The marks -7 and +6 may not be shown on the output test page 2, depending on the paper width.

- Although the mark -7 may be shown on the output test page 2, the numbers you can adjust values for are from -6 to +6. You cannot adjust values for -7.

4) View the output test page 2 and confirm that there is no uneven density.

5) Press "Store and Finish".

1.1.1.3.3 Gradation/density/light hue/solid color issue on copy and print and gradation adjustment

0031-5621

[ Manual-related ]

Description

When copying or printing, if the gradation or density is poor, hue is light or solid color issue occurs, following adjustments can be implemented according to the

use of copy or print.

Field Remedy

a) Automatically adjust gradation and density

You can recalibrate the machine when you notice irregularities in the color of the copies or prints, such as when copies or prints turn out to be different from the

original in gradation, density or color. The following two types of automatic gradation adjustments can be made:

"Full Adjustment": This is a precise recalibration that is made to the gradation, density, and color settings of the machine. The procedure involves making test pages

Summary of Contents for imagePRESS C800 Series

Page 1: ...Dec 2 2014 Troubleshooting Guide imagePRESS C800 Series...

Page 2: ......

Page 6: ......

Page 8: ......

Page 9: ...Chapter 1 Correcting Faulty Images...

Page 10: ......

Page 14: ......

Page 114: ...Chapter 1 1 100 7 2 Select the envelope type press OK...

Page 165: ...Chapter 1 1 151 3 Pull the Tray all the way out...

Page 167: ...Chapter 1 1 153 5 Remove the Waste Toner Container...

Page 172: ...Chapter 1 1 158 2 Pull out the staple cartridge holding it by the green tab...

Page 180: ...Chapter 1 1 166 5 Push in the new staple case until it clicks to insert it...

Page 181: ...Chapter 1 1 167 6 Close the Cover for the saddle stitch staple cartridge...

Page 199: ...Chapter 1 1 185 b 1 Take out the Waste Toner Container 1...

Page 201: ...Chapter 1 1 187 b 2 Install the Waste Toner Joint 1 to the Waste Toner Container 2...

Page 206: ...Chapter 1 1 192 b 9 Remove the Prism 1 1 Screw 2 1 Hook 3...

Page 207: ...Chapter 1 1 193 b 10 Clean the toner adhered to the 2 A parts on the prism...

Page 208: ...Chapter 1 1 194 b 11 Clean the toner adhered to the A part of the Waste Toner Container...

Page 210: ...Chapter 1 1 196 2 Pull out the punch waste tray...

Page 217: ...Chapter 1 1 203 3 Discard the staple waste...

Page 239: ...Chapter 1 1 225 3 Press Memory Media 4 Select the target memory media...

Page 250: ...Chapter 1 1 236 Select Share files and folders using SMB Windows Select the account to be used...

Page 255: ...Dec 2 2014...

Page 256: ......